- Joined

- Dec 22, 2020

- Messages

- 97

I'll start with I do know the various differences in the MKII Blockheads.

I did however find a specific I do not know.

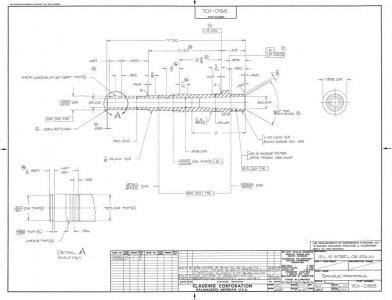

I'll include a drawing for the 701-088 spindle (feel free to upload it to the downloads section if it isn't there already)

I can't find out if the bearings are the only difference between the roller bearing and ball bearing spindles.

There is a part number difference. The ball bearing spindle is 701-083.

Are the spindles interchangeable? Is a minor dimensional change?

I really have no Idea and it's way to late in the day to call Clausing.

I did however find a specific I do not know.

I'll include a drawing for the 701-088 spindle (feel free to upload it to the downloads section if it isn't there already)

I can't find out if the bearings are the only difference between the roller bearing and ball bearing spindles.

There is a part number difference. The ball bearing spindle is 701-083.

Are the spindles interchangeable? Is a minor dimensional change?

I really have no Idea and it's way to late in the day to call Clausing.