- Joined

- Nov 24, 2013

- Messages

- 268

I did my first cut today with my Taig mini lathe and although the results were good to my opinion, there are some questions I have regarding how we feed the stock and lock axes

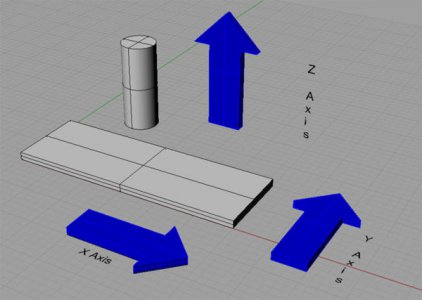

For clarification, I consider the Z axis is moving the carriage left / right, X axis is moving the cross slide front to back and Y axis is moving the mill attachment UP / DN.

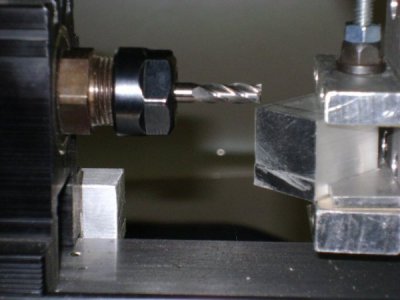

When the width on my cut is more than my end mill (in this case the end mill is 0.25” and final width of cut is 0.377”) is it ok to have the X axis unlocked and as I go UP/DN doing the cut with my Y axis also move the X axis front / back to complete the cut across the 0.377” surface?

For clarification, I consider the Z axis is moving the carriage left / right, X axis is moving the cross slide front to back and Y axis is moving the mill attachment UP / DN.

When the width on my cut is more than my end mill (in this case the end mill is 0.25” and final width of cut is 0.377”) is it ok to have the X axis unlocked and as I go UP/DN doing the cut with my Y axis also move the X axis front / back to complete the cut across the 0.377” surface?