- Joined

- Oct 5, 2010

- Messages

- 1,050

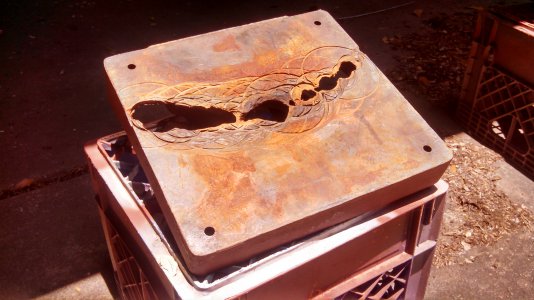

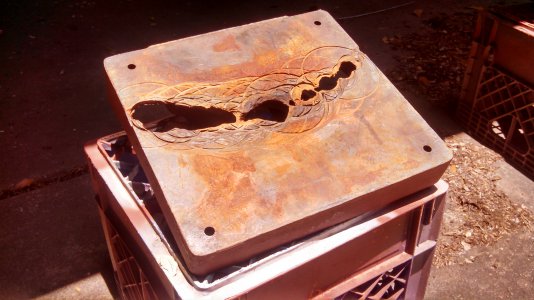

I am always amazed by how some people treat tools. I just recently picked up an old 600 series Rockwell Drill press that I am now restoring. Over the past few years I have restored about a dozen drill presses but this one definitely has the worst Arc of Shame I have dealt with. This guy wasn't satified just to drill holes in the table; he went back over it with a hole saw! Anybody have any pictures of a worse one?

Randy

Randy