F

Firestopper

Forum Guest

Register Today

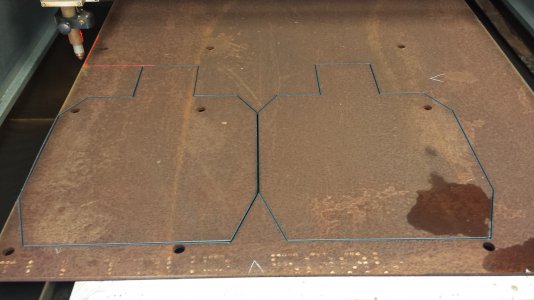

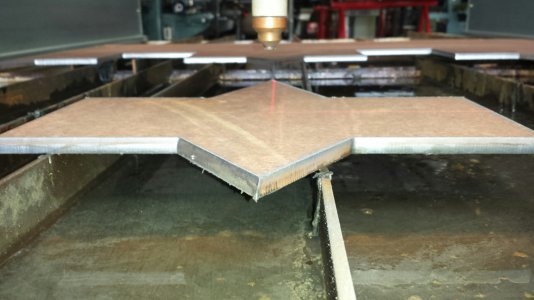

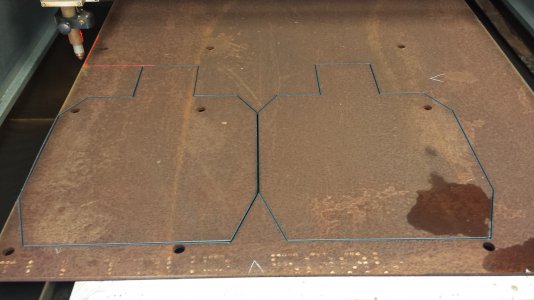

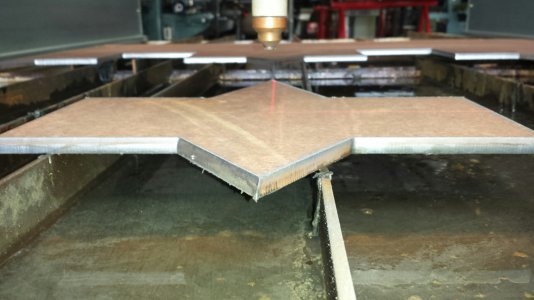

I cut some 1/2" plate (AR500) for shooting targets. The plate was purchased some time back when a large copper mine shut down production. The material was to be used for bed liners on off highway trucks. The only problem was the predrilled counter sunk hole evenly spaced. I had to avoid the holes as the CNC plasma torch would "dive" if a hole was encounter resulting in a collision. Over all 150 targets where cut (4 sheets) with very good cut quality. The machine was programed and the plasma was set up for 80amps cutting at 40 ipm.

The coyote silhouettes are life size and the customer really liked them. The rest of the targets where IDPA standard sizes. The laser attachment on the cutting torch really made indexing easy for avoiding the existing holes.

The coyote silhouettes are life size and the customer really liked them. The rest of the targets where IDPA standard sizes. The laser attachment on the cutting torch really made indexing easy for avoiding the existing holes.