- Joined

- May 3, 2017

- Messages

- 2,041

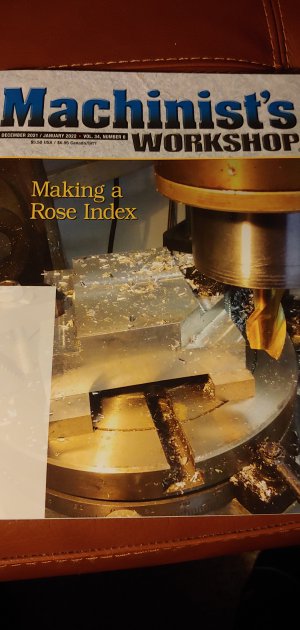

I found epanzella's recent thread on a Rose Index to be very interesting:

www.hobby-machinist.com

www.hobby-machinist.com

For quite a while now, I have been thinking about making one for myself, and it looks like enough free time for this project is right around the corner. A question has occurred to me. Is there any significant reason, other than efficient use of material, to fabricate a single plate for the three major configurations (4, 6 and 8 sides)? It seems to me theoretically, that rigidity would be optimized if there were a single indexing plate for each configuration. I ask this because I've been sorting through my scrap aluminum bin, and I can do it either way. I have quite a bit of 4" x 3/4" aluminum from which I can make individual plates, and I also have a piece of 1-1/4" thick stock with a usable diameter of about 6-1/4" from which I could make a single plate in the conventional fashion.

Would very much like to hear some opinions before I begin butchering some metal.

Regards,

Terry

Rose Index Question

It's raining so my outdoor projects are squashed for today. Rather than watch Opra I decided to knock out a Rose index. I just sliced off a 4" x 1" hunk of steel with my bandsaw but before I start making chips I have a question. What is the purpose of having both a 4 sided and an 8 sided section...

www.hobby-machinist.com

www.hobby-machinist.com

For quite a while now, I have been thinking about making one for myself, and it looks like enough free time for this project is right around the corner. A question has occurred to me. Is there any significant reason, other than efficient use of material, to fabricate a single plate for the three major configurations (4, 6 and 8 sides)? It seems to me theoretically, that rigidity would be optimized if there were a single indexing plate for each configuration. I ask this because I've been sorting through my scrap aluminum bin, and I can do it either way. I have quite a bit of 4" x 3/4" aluminum from which I can make individual plates, and I also have a piece of 1-1/4" thick stock with a usable diameter of about 6-1/4" from which I could make a single plate in the conventional fashion.

Would very much like to hear some opinions before I begin butchering some metal.

Regards,

Terry