- Joined

- Aug 13, 2020

- Messages

- 1,342

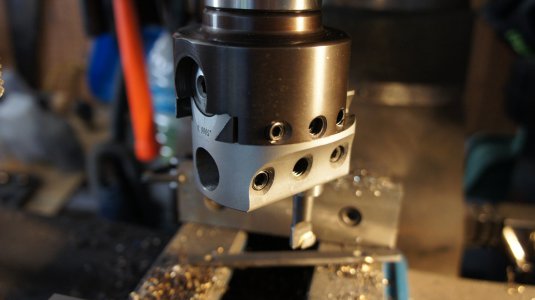

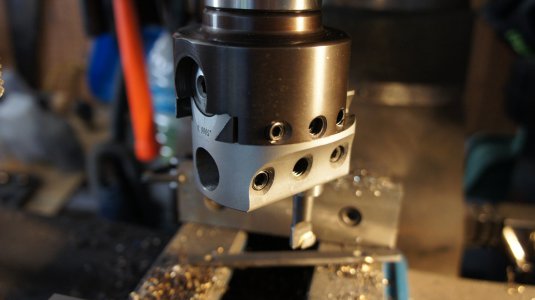

I got me one of those boring head kits that came with brazed carbide tip boring bars. It isn't the bottom of the barrel kit, but you do have to lean in there to get down to it. I've been using it to expand a 2.5" to 3.000" in a 1/4" then a 3/4" plate. I mount it with the 3/4" plate down flat on the vice, bore the 1/4" plate, then unbolt and move it out of the way. Then bore the 3/4" plate.

The problem I'm having is that I can take the boring bar out and sharpen it with a diamond hone. I get through the 1/4" plate, and maybe one or two passes on the 3/4", and it will start with terrible chatter. Pull the bar out, and the tip will be dull and chipped. Several minutes on the hone, and I can get it to cut smooth again.

I'm running at about 550 RPM, and taking 50thou off the diameter with each cut. Hand feeding using the knee, so that everything else can be locked down tight. The feed rate is very much by ear. I speed up if it starts to chatter, and slow down to as the motor starts bogging down.

Question: Am I asking too much from this cutter, or is this edge life about what I can expect? And more generally, how long can a carbide tool/bit be expected to live?

The problem I'm having is that I can take the boring bar out and sharpen it with a diamond hone. I get through the 1/4" plate, and maybe one or two passes on the 3/4", and it will start with terrible chatter. Pull the bar out, and the tip will be dull and chipped. Several minutes on the hone, and I can get it to cut smooth again.

I'm running at about 550 RPM, and taking 50thou off the diameter with each cut. Hand feeding using the knee, so that everything else can be locked down tight. The feed rate is very much by ear. I speed up if it starts to chatter, and slow down to as the motor starts bogging down.

Question: Am I asking too much from this cutter, or is this edge life about what I can expect? And more generally, how long can a carbide tool/bit be expected to live?