- Joined

- Dec 7, 2015

- Messages

- 519

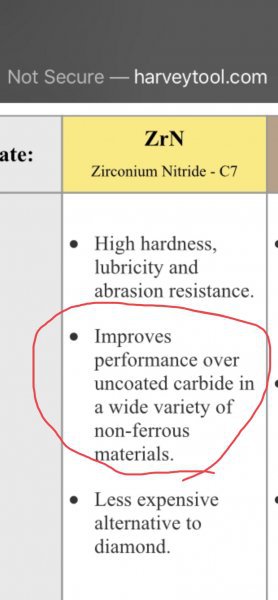

I have a few ZrN coated, high helix (45*), 3 flute end mills that are exceptionally free cutting in aluminum. There is a clear difference between these and my ALTiN coated end mills. So I figured that the ZrN coating would be the way to go for aluminum/titanium roughing. I was searching around and found this guy which looks pretty nice:

But then I started researching a bit more and discovered the TaC coating. These guys claim as much as 20 times tool life in 6061 with no aluminum build up on the tool. That's beyond interesting. I found this end mill which states that it's for HEM, so I'm not sure it's as useful in a manual Bridgeport type mill. But it does have an aggressive chip breaker and might work nice as a roughing end mill for aluminum:

www.imcousa.com

www.imcousa.com

I did notice that Niagara Cutter only lists end mills coated with TiCN for aluminum work. It's interesting to me that I can't find any ZrN end mills from Niagara, but perhaps I'm reading too much into that?

Thoughts?

But then I started researching a bit more and discovered the TaC coating. These guys claim as much as 20 times tool life in 6061 with no aluminum build up on the tool. That's beyond interesting. I found this end mill which states that it's for HEM, so I'm not sure it's as useful in a manual Bridgeport type mill. But it does have an aggressive chip breaker and might work nice as a roughing end mill for aluminum:

IMCO | Product Search

I did notice that Niagara Cutter only lists end mills coated with TiCN for aluminum work. It's interesting to me that I can't find any ZrN end mills from Niagara, but perhaps I'm reading too much into that?

Thoughts?