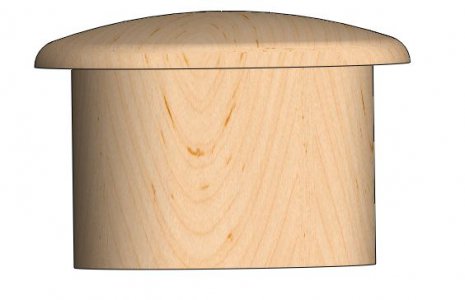

I'd like to take a plug-cutter (a tool for making wooden plugs that then are inserted into holes to cover up fasteners) and slightly alter it. Here's a picture of a plug-cutter set, so that you get the idea:

The resulting plugs --- created by plunging the cutter into the face of a board, and then bandsawing the board to make the plugs call out --- are more or less cylindrical. The fancier plug-cutters actually make plugs that are slightly chamfered on the very top (if you plunge deep enough).

I need some plugs that are "half-inch oversized", i.e., the plug has a diameter of about 0.53 inches. In fact, I'd really like to make a plug that tapers from 0.55 down to about 0.51. (Some plug cutters already have taper, but none are quite this size, alas).

I thought that perhaps I could start with a plug-cutter like the one above, and on a lathe, remove some of the material inside using the compound -- is that the right term? --- to produce the taper, and something like a boring bar to hold a bit that'd do the cutting.

But I expect that the cutter is made of tool steel and very hard, so maybe this idea is just stupid. Or maybe it needs to be ground (which is probably beyond my skills). Or maybe I should start from scratch and make something that does the job well enough to produce 8 or 10 plugs, which is all I need.

Can anyone give me advice on the feasibility of the "modify an existing cutter" approach, and how I could go about it?

The resulting plugs --- created by plunging the cutter into the face of a board, and then bandsawing the board to make the plugs call out --- are more or less cylindrical. The fancier plug-cutters actually make plugs that are slightly chamfered on the very top (if you plunge deep enough).

I need some plugs that are "half-inch oversized", i.e., the plug has a diameter of about 0.53 inches. In fact, I'd really like to make a plug that tapers from 0.55 down to about 0.51. (Some plug cutters already have taper, but none are quite this size, alas).

I thought that perhaps I could start with a plug-cutter like the one above, and on a lathe, remove some of the material inside using the compound -- is that the right term? --- to produce the taper, and something like a boring bar to hold a bit that'd do the cutting.

But I expect that the cutter is made of tool steel and very hard, so maybe this idea is just stupid. Or maybe it needs to be ground (which is probably beyond my skills). Or maybe I should start from scratch and make something that does the job well enough to produce 8 or 10 plugs, which is all I need.

Can anyone give me advice on the feasibility of the "modify an existing cutter" approach, and how I could go about it?