Hello everyone, I have read so many helpful things from this site over the years that led me to my first lathe purchase a couple years ago (PM1236)

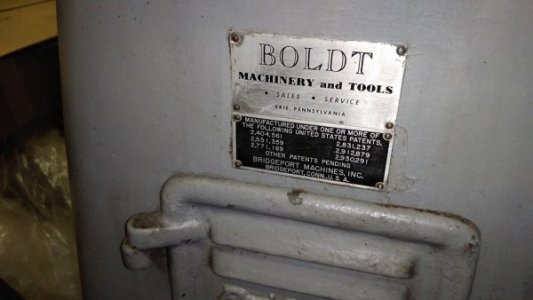

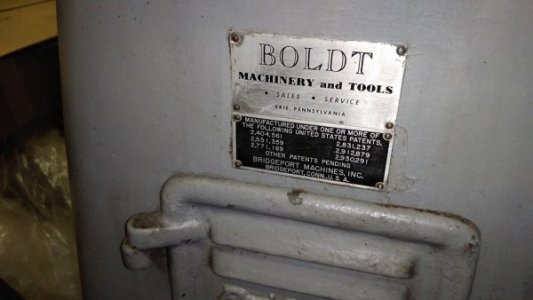

Right now I'm looking for a knee mill under 84" tall. I found one within 1.5hrs from me. It's a Bridgeport J head 8 speed SN 61006. I looked at it today and I'm still not sure it's worth $2450 the gentleman is asking for it. Pictures hopefully give some indication of wear but I will also try to describe as best I can.

Table travels smoothly from end to end. My indicator mounted to the saddle and touching the side of the table to show Gib free play when unlocked read .005" through most of it's range while pushing and pulling against the ends. Unfortunately the gib adjustment is maxed out but it does appear to be evenly worn through it's range.

Apron gibs are tighter, I didn't check how much adjustment was left but when unlocked I only saw .001" of free play. It moves smoothly until I get about 3.5" from the Mill body, then it gets real stiff. Note the line on ways in pics near body, it has a step that can be felt.

Knee gibs had no play and seemed to move smoothly and evenly throughout it's range.

Quill travel was somewhat smooth until I got to about the last inch or so, it got very stiff and wouldn't go the remaining distance without effort.

**The runout of the inside taper and outer spindle surface both read 0.0035" on my 0.0005" test indicator. Quite excessive. He has a spare head that has .0008 to .001 roughly that he would include to swap out if needed.

I forgot to bring a dowel to test quill play.

Table run out was under .0015"

Table has many surface imperfections but nothing groundbreaking.

** All functions of the machine work except the quill feed adjustment would not let us set it to 6. Something felt like it was blocking it and would need looked at.

Motor is a 1 HP 220V single phase and runs smooth and quiet when the belt is detached.

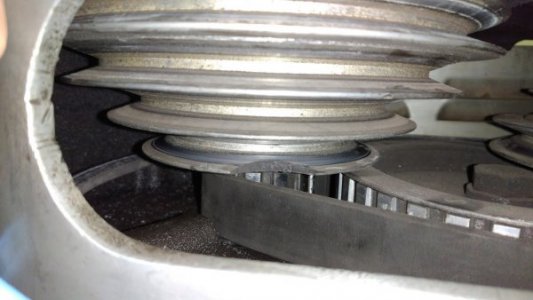

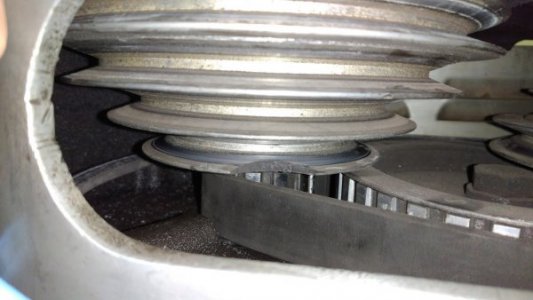

**The front step pulley has a sizeable chunk missing, while running in higher speed ranged the machine vibrates significantly which this may be the cause.

The rear gear pulley has a crack on the top (not pictured) but may be fine.

The shop that had it first installed grease zerks for all the ways, odd I thought. There is no one shot oil system.

I have no major projects lined up but I do plan to make a cnc router in the near future. A mill would greatly help me get mounting plates etc made to much tighter tolerances, but for the most part I will use as needed.

If may have forgotten something but this is the gist of it. Think it's worth $2450?

I appreciate your time and thank you for any input.

Regards,

Paul

Right now I'm looking for a knee mill under 84" tall. I found one within 1.5hrs from me. It's a Bridgeport J head 8 speed SN 61006. I looked at it today and I'm still not sure it's worth $2450 the gentleman is asking for it. Pictures hopefully give some indication of wear but I will also try to describe as best I can.

Table travels smoothly from end to end. My indicator mounted to the saddle and touching the side of the table to show Gib free play when unlocked read .005" through most of it's range while pushing and pulling against the ends. Unfortunately the gib adjustment is maxed out but it does appear to be evenly worn through it's range.

Apron gibs are tighter, I didn't check how much adjustment was left but when unlocked I only saw .001" of free play. It moves smoothly until I get about 3.5" from the Mill body, then it gets real stiff. Note the line on ways in pics near body, it has a step that can be felt.

Knee gibs had no play and seemed to move smoothly and evenly throughout it's range.

Quill travel was somewhat smooth until I got to about the last inch or so, it got very stiff and wouldn't go the remaining distance without effort.

**The runout of the inside taper and outer spindle surface both read 0.0035" on my 0.0005" test indicator. Quite excessive. He has a spare head that has .0008 to .001 roughly that he would include to swap out if needed.

I forgot to bring a dowel to test quill play.

Table run out was under .0015"

Table has many surface imperfections but nothing groundbreaking.

** All functions of the machine work except the quill feed adjustment would not let us set it to 6. Something felt like it was blocking it and would need looked at.

Motor is a 1 HP 220V single phase and runs smooth and quiet when the belt is detached.

**The front step pulley has a sizeable chunk missing, while running in higher speed ranged the machine vibrates significantly which this may be the cause.

The rear gear pulley has a crack on the top (not pictured) but may be fine.

The shop that had it first installed grease zerks for all the ways, odd I thought. There is no one shot oil system.

I have no major projects lined up but I do plan to make a cnc router in the near future. A mill would greatly help me get mounting plates etc made to much tighter tolerances, but for the most part I will use as needed.

If may have forgotten something but this is the gist of it. Think it's worth $2450?

I appreciate your time and thank you for any input.

Regards,

Paul