I need some advice, please, on a recent hand-me-down. It's a DAYTONA DF-12 (not Dayton), 12 speed, that I think is a Rexon, it's made in Taiwan. The badge on the DP says JT.3 for the spindle.

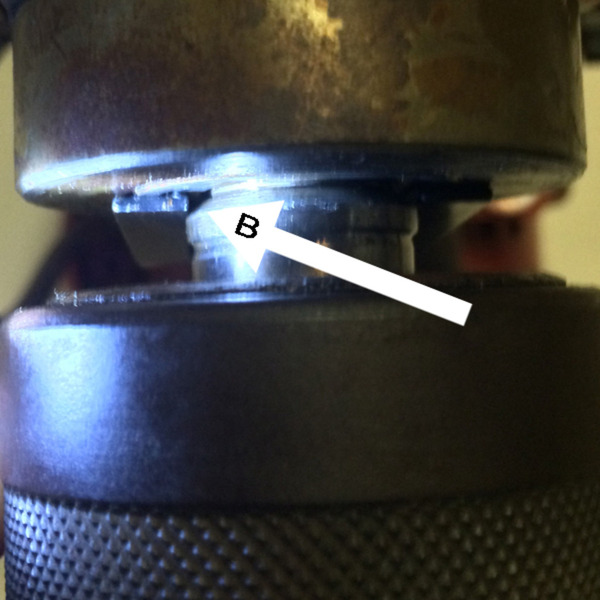

I thought I could use #3 Jacobs wedges, but as you can see in this picture, the tapers can't get above the shoulder on the arbor and when tapping the wedge in, it rides down over the shoulder. Similar for when I use both wedges below the shoulder to try and remove the chuck, the top wedge rides up over the shoulder on the arbor.

The arbor is definitely bent! Using a dial indicator, I get runout of 0.008 at the arbor below the shoulder, 0.01 at the top of the chuck sleeve, 0.25 at the bottom of the chuck sleeve, 0.05 at the body near the keyhole, and 0.65 on a bit in the chuck.

There is 0.005 front to back movement when measuring the end of the extended quill, which might be expected, though I do plan on replacing the bearings, if I get that far.

Here's few more pics that hopefully help...

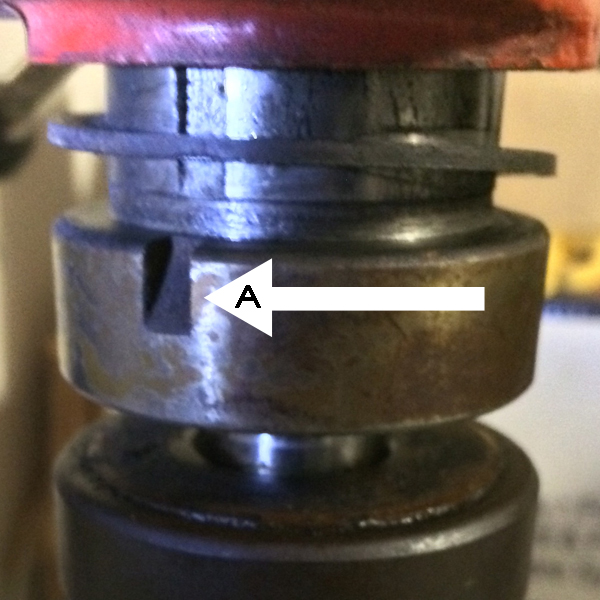

Finally, what is this notch (A) used for on the end of the quill in this picture, below?

Any advice (other than put it on the curb) is greatly appreciated! It has sentimental value and getting it running true again is what I'm after. If it turns out I need a new chuck, too, then it might not be worth fixing

Sincerely

Gavin

I thought I could use #3 Jacobs wedges, but as you can see in this picture, the tapers can't get above the shoulder on the arbor and when tapping the wedge in, it rides down over the shoulder. Similar for when I use both wedges below the shoulder to try and remove the chuck, the top wedge rides up over the shoulder on the arbor.

The arbor is definitely bent! Using a dial indicator, I get runout of 0.008 at the arbor below the shoulder, 0.01 at the top of the chuck sleeve, 0.25 at the bottom of the chuck sleeve, 0.05 at the body near the keyhole, and 0.65 on a bit in the chuck.

There is 0.005 front to back movement when measuring the end of the extended quill, which might be expected, though I do plan on replacing the bearings, if I get that far.

Here's few more pics that hopefully help...

Finally, what is this notch (A) used for on the end of the quill in this picture, below?

Any advice (other than put it on the curb) is greatly appreciated! It has sentimental value and getting it running true again is what I'm after. If it turns out I need a new chuck, too, then it might not be worth fixing

Sincerely

Gavin