This is my attempt at fixing the round column registration problem.

Part 1 was replacing the head lift crank with a windshield wiper motor from a saturn Vue (surplus at Princess Auto for $13)

Action video...... https://www.dropbox.com/s/26wb19hzack3i44/VerticalLift Movie-short.wmv?dl=0

Part 2 was adding thrust bearings and permanent handles to the column clamp (the thrust bearings work really well)

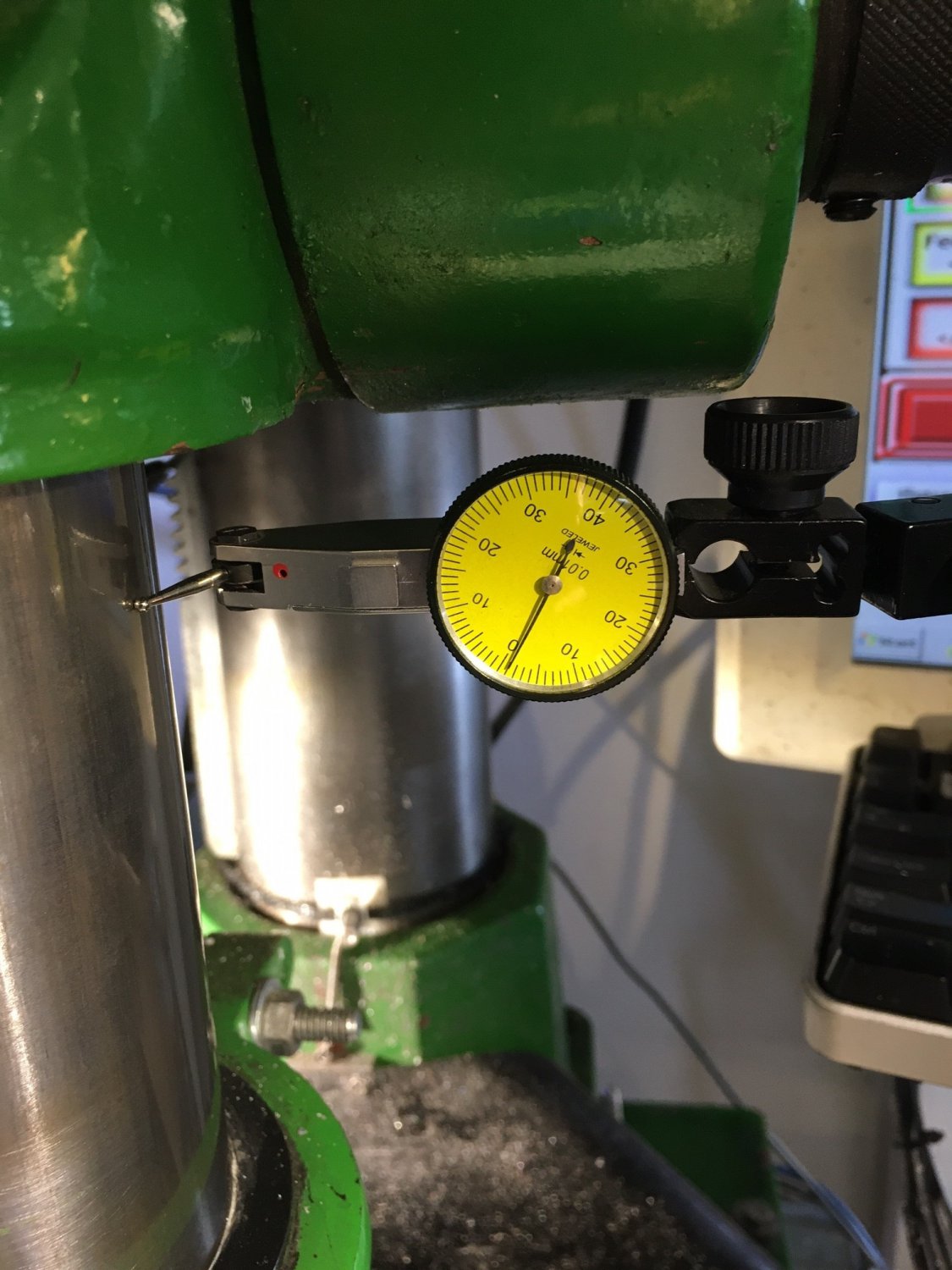

Part 3 adding twin parallel 16mm steel rods with linear bearings to maintain registration while un-clamped, seems to work very well, typically less than 0.001" over 4", still need to test over the full 12" span.

My approach:

1) Used a 2x4x1/4” rectangular tube as the “ 2nd “ column, mounted it firmly to the head

2) Milled a ¼” slot to match the tube in a 2” thick aluminum block as the base mount

3) Mounted twin 16mm rods with linear bearings to the tube

4) After a trial fit and a few shims to make sure the rods were parallel to the original column, cut ~12” segment out of the middle of the rectangular tube

Part 1 was replacing the head lift crank with a windshield wiper motor from a saturn Vue (surplus at Princess Auto for $13)

Action video...... https://www.dropbox.com/s/26wb19hzack3i44/VerticalLift Movie-short.wmv?dl=0

Part 2 was adding thrust bearings and permanent handles to the column clamp (the thrust bearings work really well)

Part 3 adding twin parallel 16mm steel rods with linear bearings to maintain registration while un-clamped, seems to work very well, typically less than 0.001" over 4", still need to test over the full 12" span.

My approach:

1) Used a 2x4x1/4” rectangular tube as the “ 2nd “ column, mounted it firmly to the head

2) Milled a ¼” slot to match the tube in a 2” thick aluminum block as the base mount

3) Mounted twin 16mm rods with linear bearings to the tube

4) After a trial fit and a few shims to make sure the rods were parallel to the original column, cut ~12” segment out of the middle of the rectangular tube

Attachments

Last edited: