- Joined

- Aug 3, 2017

- Messages

- 2,437

My 16" lathe didn't come with a steady rest, buying the one that comes with this lathe is basically impossible (I'd end up having to find a lathe that comes with one, buy it, and find a way to dispose of it), and the factory one was pretty mediocre. So, I figured I'd need to build one some day.

If been keeping an eye on eBay for one of the right size or so. One of the size of my lathe ends up likely not working, since the spindle isn't centered in the ways. I figured I'd have to buy a slightly larger one, then take some material off it( or make one from scratch!). Additionally, my lathe is 8 1/8 from the bottom to center, so I would need a larger side of 16" (or add material to the bottom). Most of that size ended up having about a 3" capacity though.

Imagine my surprise when I found one made for a 18" lathe that had a huge center circle, and looked in good shape! It was even pretty cheap! I did an offer on it for cheap and was instantly accepted.

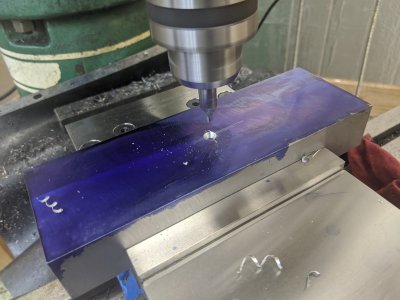

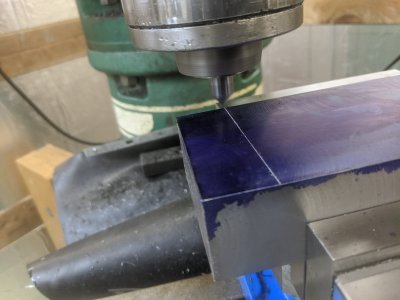

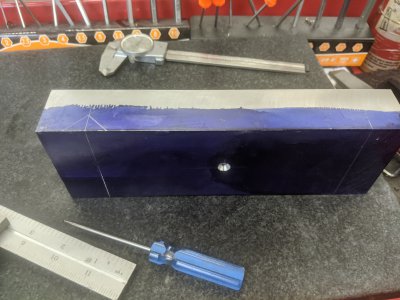

I finally got out to the shop today and ended up measuring out the new steady rest. IT has a 9 1/8 base to center, so I have to take an entire inch off the bottom, plus about 1/2" for the triangle cutout. Suffice to say, I need to cut the entire bottom off and bolt on a new one I think :/

I'm going to plan on finding a 2*3*12" piece of cold roll I think, machine the base of the current one off, then bolt up the new piece as new base. Not much material in the legs, but I have to work with what I've got I guess. Picture are of the steady rest and my white board measurements.

If been keeping an eye on eBay for one of the right size or so. One of the size of my lathe ends up likely not working, since the spindle isn't centered in the ways. I figured I'd have to buy a slightly larger one, then take some material off it( or make one from scratch!). Additionally, my lathe is 8 1/8 from the bottom to center, so I would need a larger side of 16" (or add material to the bottom). Most of that size ended up having about a 3" capacity though.

Imagine my surprise when I found one made for a 18" lathe that had a huge center circle, and looked in good shape! It was even pretty cheap! I did an offer on it for cheap and was instantly accepted.

I finally got out to the shop today and ended up measuring out the new steady rest. IT has a 9 1/8 base to center, so I have to take an entire inch off the bottom, plus about 1/2" for the triangle cutout. Suffice to say, I need to cut the entire bottom off and bolt on a new one I think :/

I'm going to plan on finding a 2*3*12" piece of cold roll I think, machine the base of the current one off, then bolt up the new piece as new base. Not much material in the legs, but I have to work with what I've got I guess. Picture are of the steady rest and my white board measurements.