- Joined

- Feb 25, 2012

- Messages

- 50

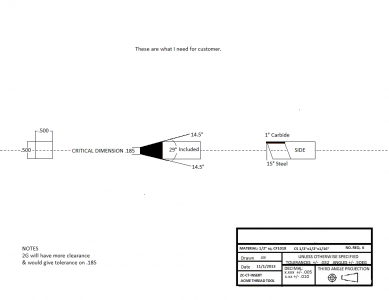

I have never turned or tapped Acme threads and I won't be for the project at hand. I have a customer that request me to build some trunions for a screw jack. Said trunions are to be made from 2" x 2" bar 4" in length with a .750" x 1.5000" boss turned on each end. It gets interesting in that a hole is required in the center to accommodate an Acme tap for .750" 8 TPI Acme screw; unspecified G; unspecified hole size. UGH!

So, I go to my trusty Machinery's Handbook. Not much help there either. Next stop Google. There are as many recommended tap drill hole sizes as there were search results ranging from .5033" to .6375". That's a pretty healthy range.

So, what is it? I know my ignorance is missing something important here... (of course that is the basic definition of ignorance)

AS an aside, one chart indicated for a .625" 15 TPI the tap drill to be .0025"! Really? Two and a half thousandths?!

So, I go to my trusty Machinery's Handbook. Not much help there either. Next stop Google. There are as many recommended tap drill hole sizes as there were search results ranging from .5033" to .6375". That's a pretty healthy range.

So, what is it? I know my ignorance is missing something important here... (of course that is the basic definition of ignorance)

AS an aside, one chart indicated for a .625" 15 TPI the tap drill to be .0025"! Really? Two and a half thousandths?!