- Joined

- Dec 18, 2019

- Messages

- 7,428

Although I understand the concept of a follow rest, the one that I have is defying use. Perhaps, I don't have the right tooling, or whatever, but I can tell you, I'm getting frustrated with it. I could rant about what I don't like about it, but at this point, I'm just seeing if I could use it.

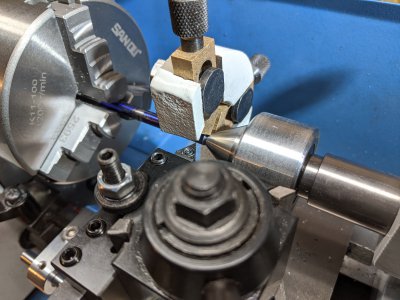

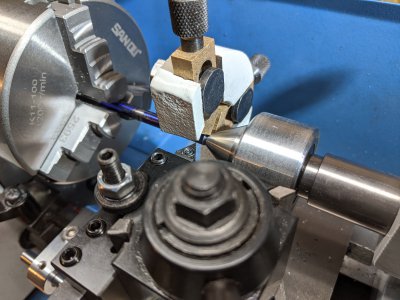

Ok, what am I trying to do? Single point thread a long rod. Specifically 1.5" of 1/4" rod. Since it's long and skinny compared to its diameter it would seem using a follow rest would make sense. That's the only thing making sense. Ok, had to cut down the number of threads sticking out from the left side. Easy. (Why did they design it with the nuts on that side? It restricts how close you can get to the chuck.) Now I can get 6mm closer to the chuck. Since the workpiece is long, maybe I should support it with a live center. Ok, done. Let's now check both ends to see the tool can cut where it needs to. Chuck side seems to be ok. Live center side, nope, the follow rest jaws hit the live center. To make it clear I'd have to cut 1/2 the jaw width. Seems like a lot.

What is the solution space here? Cut the jaws? Use a different live center with a tiny nose? Cheapest one I can find whose dimensions are close is $96. Use a dead center that is half cut way so I can thread to the end (~ $10). Anything else? Cheapest after filing the jaws is probably the cut dead center.

It's funny, as I single point threaded a 1/4 rod before and used nothing. Threads didn't come out the greatest, but they were functional. Thought I'd use the follow rest, umm, because I have one, but the one I have has serious deficiencies, in installation, in visibility, and in use. Not sure I will be able to easily tell when to stop, since the visibility is poor. To safeguard against hitting the chuck I have put in a carriage stop.

Kind of stuck for the moment. Any helpful ideas?

Ok, what am I trying to do? Single point thread a long rod. Specifically 1.5" of 1/4" rod. Since it's long and skinny compared to its diameter it would seem using a follow rest would make sense. That's the only thing making sense. Ok, had to cut down the number of threads sticking out from the left side. Easy. (Why did they design it with the nuts on that side? It restricts how close you can get to the chuck.) Now I can get 6mm closer to the chuck. Since the workpiece is long, maybe I should support it with a live center. Ok, done. Let's now check both ends to see the tool can cut where it needs to. Chuck side seems to be ok. Live center side, nope, the follow rest jaws hit the live center. To make it clear I'd have to cut 1/2 the jaw width. Seems like a lot.

What is the solution space here? Cut the jaws? Use a different live center with a tiny nose? Cheapest one I can find whose dimensions are close is $96. Use a dead center that is half cut way so I can thread to the end (~ $10). Anything else? Cheapest after filing the jaws is probably the cut dead center.

It's funny, as I single point threaded a 1/4 rod before and used nothing. Threads didn't come out the greatest, but they were functional. Thought I'd use the follow rest, umm, because I have one, but the one I have has serious deficiencies, in installation, in visibility, and in use. Not sure I will be able to easily tell when to stop, since the visibility is poor. To safeguard against hitting the chuck I have put in a carriage stop.

Kind of stuck for the moment. Any helpful ideas?