- Joined

- May 7, 2014

- Messages

- 776

OK, so the new Mill is cutting plant foam really nice...time to Graduate and I'm getting cold feet.

The Mill: 2HP SuperMax YMC 30 taper.

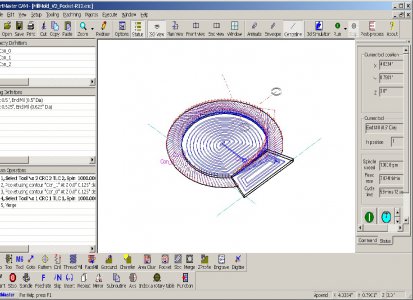

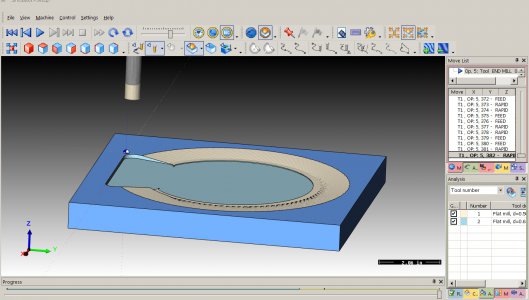

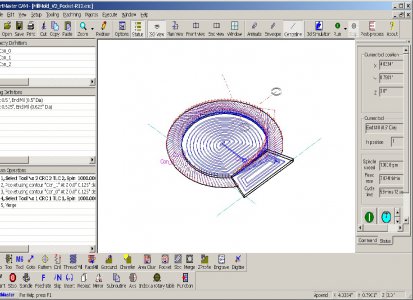

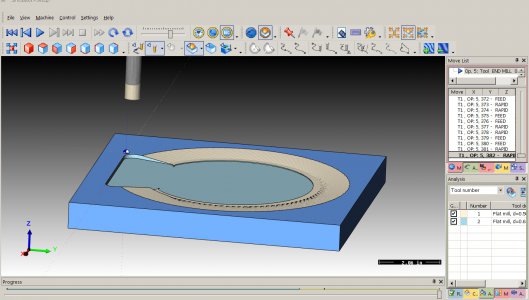

The Part: A 6+ inch mold pattern the son needs for an Axe project. .125 total depth on two pockets. (2 passes for .125 ) Then a 'merge' or taper edge all the way around the larger pocket. (images below).

I was told that A36 was equiv to 1020 but that's not what I'm reading online?? Some say closer to 1030?? Here is my short list of Q's:

1) I bought HSS cutters for this and now wonder if I should break out the Carbides? I do not want to waste 2 or 3 endmills only to find out I need the Carbides.

2) With HSS end mills do you usually cut w/ Mist or air on part. I do not have the flood up yet.

3) Using GWizard HSS 5/8 end mill = IPt .003 , RPM 978 and Feed IPM of 15.57

4) Using GWizard: Carbide/Coated . IPT .0027 RPM 2892 Feed IPM of 40.87 (seems really fast!)

Just don't know the materials all that well yet! Appreciate any comment or suggestions. This is just some test stuff we wanted to do.

The Mill: 2HP SuperMax YMC 30 taper.

The Part: A 6+ inch mold pattern the son needs for an Axe project. .125 total depth on two pockets. (2 passes for .125 ) Then a 'merge' or taper edge all the way around the larger pocket. (images below).

I was told that A36 was equiv to 1020 but that's not what I'm reading online?? Some say closer to 1030?? Here is my short list of Q's:

1) I bought HSS cutters for this and now wonder if I should break out the Carbides? I do not want to waste 2 or 3 endmills only to find out I need the Carbides.

2) With HSS end mills do you usually cut w/ Mist or air on part. I do not have the flood up yet.

3) Using GWizard HSS 5/8 end mill = IPt .003 , RPM 978 and Feed IPM of 15.57

4) Using GWizard: Carbide/Coated . IPT .0027 RPM 2892 Feed IPM of 40.87 (seems really fast!)

Just don't know the materials all that well yet! Appreciate any comment or suggestions. This is just some test stuff we wanted to do.