- Joined

- Sep 28, 2013

- Messages

- 4,395

made a bunch a few years ago when I got my QCTP and as I've added new tools over the meantime I've run out of holders. Swapping tools out of holders started to get old in a hurry (and defeats the whole point) so a nice piece of 4x1x11" steel scrap that I found at work (I think it was a door stop) looked like a good candidate. 0XA holders are 2x1x1" in size, so that piece should get me 22 holders. Also needed a 5/8" boring bar holder for my larger drill chucks, so made one of those too.

milling the dovetail slots with a 3/8" rougher

cutting the dovetails with a homemade single flute cutter using a TCGT insert

dovetails done. I love my X-axis powerfeed!

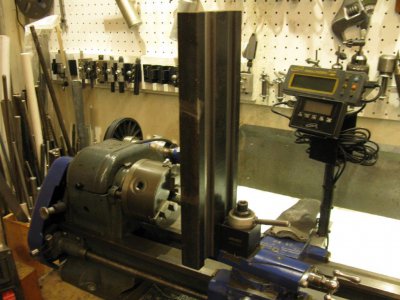

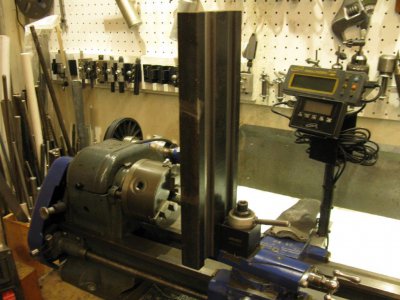

checking for fit

started cutting off slices on my horizontal bandsaw, love that tool too

while that was going on I got temporarily distracted and made my 5/8" boring bar holder

mostly to be used for larger reamers as I'm a little leary of trying to push big drills with the carriage wheel

starting to figure out what holders I need

cut the slots for my 10mm turning tool holders

then cut those in half to make a pile of blanks

knurled, drilled and tapped a bunch of height adjusters. Boy that was tedious.

drilled and tapped. Used a vise work stop and the "DRO" on the drill press to drill the holes, then a hand drill to countersink and tap them 10-32.

making another parting tool holder, so I can have 2 blades the same width but at different projections as these are a bit tedious to adjust stick out

bit of a duplicate pic, but this is the "before black oxide treatment"

steel soup

all finished!

I think they came out really well! Now have to load them up with tools. Also need to get my 3D printer set up in the garage so I can print more holders for my holders.

Have 1 finished blank and a 2" chunk of the original piece left (4 holders within) as my bandsaw jaws couldn't hold onto it. Next project - making new bandsaw jaws

milling the dovetail slots with a 3/8" rougher

cutting the dovetails with a homemade single flute cutter using a TCGT insert

dovetails done. I love my X-axis powerfeed!

checking for fit

started cutting off slices on my horizontal bandsaw, love that tool too

while that was going on I got temporarily distracted and made my 5/8" boring bar holder

mostly to be used for larger reamers as I'm a little leary of trying to push big drills with the carriage wheel

starting to figure out what holders I need

cut the slots for my 10mm turning tool holders

then cut those in half to make a pile of blanks

knurled, drilled and tapped a bunch of height adjusters. Boy that was tedious.

drilled and tapped. Used a vise work stop and the "DRO" on the drill press to drill the holes, then a hand drill to countersink and tap them 10-32.

making another parting tool holder, so I can have 2 blades the same width but at different projections as these are a bit tedious to adjust stick out

bit of a duplicate pic, but this is the "before black oxide treatment"

steel soup

all finished!

I think they came out really well! Now have to load them up with tools. Also need to get my 3D printer set up in the garage so I can print more holders for my holders.

Have 1 finished blank and a 2" chunk of the original piece left (4 holders within) as my bandsaw jaws couldn't hold onto it. Next project - making new bandsaw jaws