- Joined

- Jul 29, 2014

- Messages

- 2,847

I am surprised how much I use my corner notcher, not just for the basic idea of notching corners, but just to chop up and contour some sheet metal from time to time. A practical use is to make shallow sheet metal trays to fit tool boxes and hold random items. The corner notcher makes it easy to take a piece of sheet metal, notch four corners and fold them up in the brake, for a open top box.

But, it's a little bit of a nuisance to set the corner notcher stops so that each side is exactly the same depth, so that the box walls are the same height. In fact it's so much of a nuisance using a square, ruler, triangle, three hands, etc. that I made a template to help.

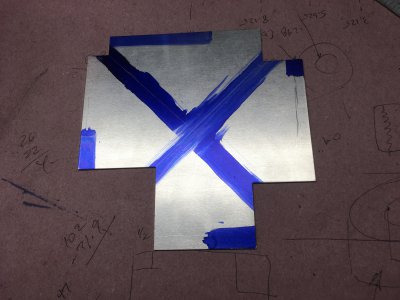

Just a flat sheet metal piece with four corners, each corner cut with great care to a different depth, obviously using the notcher to cut the corners.

I chose 1/2", 1", 1.5" and 2" as covering most of my operations. Now, with the notcher in the down position, just slide the selected corner of the template in position and snug against the notcher and move the stops up against the template. You're now set up for exact depth corners.

But, it's a little bit of a nuisance to set the corner notcher stops so that each side is exactly the same depth, so that the box walls are the same height. In fact it's so much of a nuisance using a square, ruler, triangle, three hands, etc. that I made a template to help.

Just a flat sheet metal piece with four corners, each corner cut with great care to a different depth, obviously using the notcher to cut the corners.

I chose 1/2", 1", 1.5" and 2" as covering most of my operations. Now, with the notcher in the down position, just slide the selected corner of the template in position and snug against the notcher and move the stops up against the template. You're now set up for exact depth corners.