- Joined

- Jan 10, 2024

- Messages

- 48

This is a repost of one that I did on Canadian Hobby Metal Worker's Forum in January. I'm planning to post the clean up and setup process here and I wanted to post this too for completeness. If you would like to see the original, my user name there is the same as it is here.

I've been looking for a lathe for several months now (one of the reasons I joined this forum [Canadian Hobby Metal Worker's Forum] was to keep an eye on the Classifieds and Spotted Deals sections). My general criteria were not too expensive, not too big, not too heavy, but capable enough that I am not going to be too limited in capability. To be a little more specific, I decided that an 8-11" x 20-36" capacity benchtop lathe was about right for me. Browsing the the internet, the main names that came up for kind of machine I want were South Bend, Logan, Myford and Atlas.

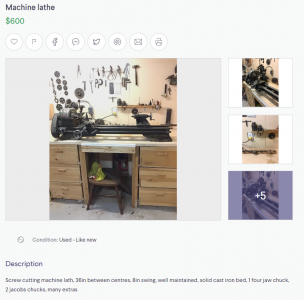

Last Friday, I came across a Kijiji Ad for a "Machine Lathe" a little more than 3 hours away from me for $600. The seller didn't mention a make or model, but I recognized it as an Atlas and after playing a bit of spot the difference with an old Atlas catalog I figured it was an Atlas 10F with the Timkin bearing spindle and a 54" bed.

As you can see from the screenshots of the ad, the description wasn't great, but it looked like they guy had a solid amount of extras that were going to come with it and the lathe looked to be in good condition. For $600 I figured even if it was pretty clapped out, it would still be worth picking up.

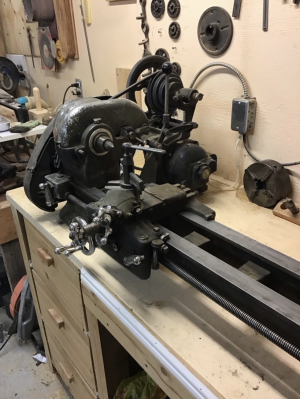

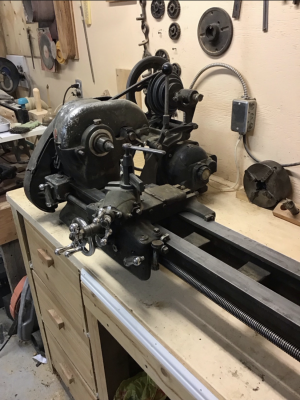

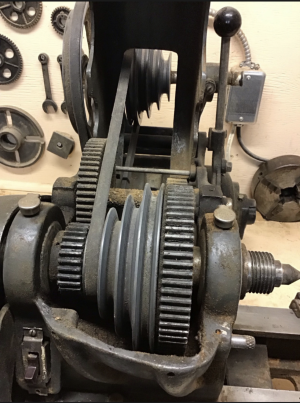

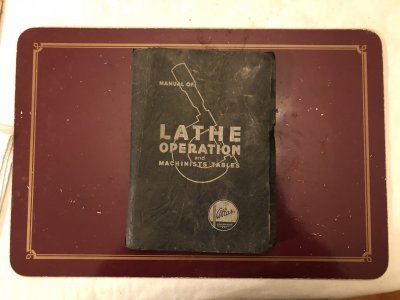

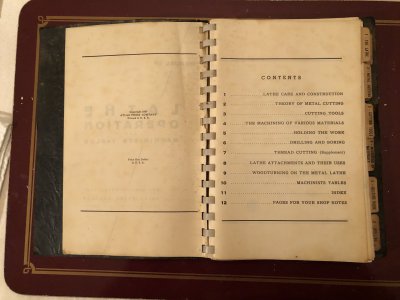

I messaged the seller and arranged to meet on Sunday to take a look at the machine. A snowy 320 km later, I got to see the lathe in person. The lathe is in great shape. No play in the spindle, lead screw looks immaculate, the ways don't have any significant chips or dents in them, the spindle and tailstock taper are in good shape, the carriage, compound and cross slide all move freely, power traverse and power cross feed both work. The motor wiring isn't even scary. The seller even included a solid amount of tooling, a couple test indicators, dividers and calipers. The only things that I can think of that I wish were included three jaw chuck and a follow rest. Basically everything in that shop that was even tangentially lathe related I got. And all this was $600!

While we packed up everything the seller, a very nice 90 year old gentleman, told us that the reason that he was getting rid of everything was that he and his wife are planning to move to a retirement community next year and since he turned 90 he hardly used any of his tools anymore. Very fortunate for me! He made a point of showing me all of the controls and went into detail on how to use the machine and how to maintain it (this was unnecessary as I did some machine shop work while still in school, but was a nice thought all the same).

I brought my 4'x6' trailer to haul the lathe home on, but it turns out that an Atlas 10F TH54 fits into the trunk of an '07 Honda Civic coupe with the seats folded down.

That was definitely better than bring the lathe home on my open utility trailer and exposing it to the salt and grit of the road.

Right now, I've got the lathe is sitting in my garage and the boxes of tooling all over my living room. I need to build a suitable bench to mount it on before I can get it set up and I'd like to get a decent toolbox with drawers so I can organize the tooling a bit. All other things equal, I would probably choose a South Bend 9" over the Atlas 10", but for $600, I am over the moon. I figure this is a prefect setup to get started and can acquire more stuff as I need it.

The first major project I have for this thing is to make a new lid for a candy machine that I picked up at a thrift store in early December. It's a simple enough shape, so it shouldn't be too hard.

I've been looking for a lathe for several months now (one of the reasons I joined this forum [Canadian Hobby Metal Worker's Forum] was to keep an eye on the Classifieds and Spotted Deals sections). My general criteria were not too expensive, not too big, not too heavy, but capable enough that I am not going to be too limited in capability. To be a little more specific, I decided that an 8-11" x 20-36" capacity benchtop lathe was about right for me. Browsing the the internet, the main names that came up for kind of machine I want were South Bend, Logan, Myford and Atlas.

Last Friday, I came across a Kijiji Ad for a "Machine Lathe" a little more than 3 hours away from me for $600. The seller didn't mention a make or model, but I recognized it as an Atlas and after playing a bit of spot the difference with an old Atlas catalog I figured it was an Atlas 10F with the Timkin bearing spindle and a 54" bed.

As you can see from the screenshots of the ad, the description wasn't great, but it looked like they guy had a solid amount of extras that were going to come with it and the lathe looked to be in good condition. For $600 I figured even if it was pretty clapped out, it would still be worth picking up.

I messaged the seller and arranged to meet on Sunday to take a look at the machine. A snowy 320 km later, I got to see the lathe in person. The lathe is in great shape. No play in the spindle, lead screw looks immaculate, the ways don't have any significant chips or dents in them, the spindle and tailstock taper are in good shape, the carriage, compound and cross slide all move freely, power traverse and power cross feed both work. The motor wiring isn't even scary. The seller even included a solid amount of tooling, a couple test indicators, dividers and calipers. The only things that I can think of that I wish were included three jaw chuck and a follow rest. Basically everything in that shop that was even tangentially lathe related I got. And all this was $600!

While we packed up everything the seller, a very nice 90 year old gentleman, told us that the reason that he was getting rid of everything was that he and his wife are planning to move to a retirement community next year and since he turned 90 he hardly used any of his tools anymore. Very fortunate for me! He made a point of showing me all of the controls and went into detail on how to use the machine and how to maintain it (this was unnecessary as I did some machine shop work while still in school, but was a nice thought all the same).

I brought my 4'x6' trailer to haul the lathe home on, but it turns out that an Atlas 10F TH54 fits into the trunk of an '07 Honda Civic coupe with the seats folded down.

(originally there were more pics here, but I can't post as many pics per post as the other forum let me, so I'll follow up with them in another post in this thread)

That was definitely better than bring the lathe home on my open utility trailer and exposing it to the salt and grit of the road.

Right now, I've got the lathe is sitting in my garage and the boxes of tooling all over my living room. I need to build a suitable bench to mount it on before I can get it set up and I'd like to get a decent toolbox with drawers so I can organize the tooling a bit. All other things equal, I would probably choose a South Bend 9" over the Atlas 10", but for $600, I am over the moon. I figure this is a prefect setup to get started and can acquire more stuff as I need it.

The first major project I have for this thing is to make a new lid for a candy machine that I picked up at a thrift store in early December. It's a simple enough shape, so it shouldn't be too hard.