- Joined

- Dec 9, 2021

- Messages

- 738

I needed to deepen the grooves in a hydraulic cylinder piston for a log loader. The cylinder bore had been honed oversize, so the piston measures 7.025" and it really maxed out the capacity of the lathe. To get the compound to clear, I had to turn it 90 degrees to the cross slide, and also move the AXA toolpost as far away from the spindle axis as possible. This resulted in poor rigidity. The piston is made of aluminum, which helped a lot, but I had to take it easy in order to minimize chatter. I held the piston in my 6" Buck Adjust-Tru 3-jaw with the jaws reversed. It was pushing the capacity of the chuck!

I used my parting tool with a HSS blade for all operations. I had to fight chatter when plunging to get the cut started, and ran the spindle at 164 RPM for all cuts. I was reducing the diameter of the bottom of the groove from 6.525 to 6.275" to accommodate a replacement seal, since the original cross-section seals are no longer available. I plunged to 6.325" and then made a series of plunge cuts, dialing in .100 on the cross-feed. Each plunge cut was about 1/3 the width of the tool. I encountered chatter if I tried to take a bigger bite. I hand-fed across the bottom of the groove and blended the cut to the existing sides of the groove. I followed this up by repeating the process twice. Once to get within .005 of the finished size, and again to the finish diameter. Each time I did a plunge cut, it was in an area where the seal lip would not contact, in case I got a rough finish. I hand-fed every cut, and got a nice finish every time. All cuts were done dry.

I had to flip the piston end-for-end to cut the second groove, but I had dialed in the Buck and did not have to change the setting. It took a long time to do this, but it was a favor for a neighbor, and I was not on the clock!

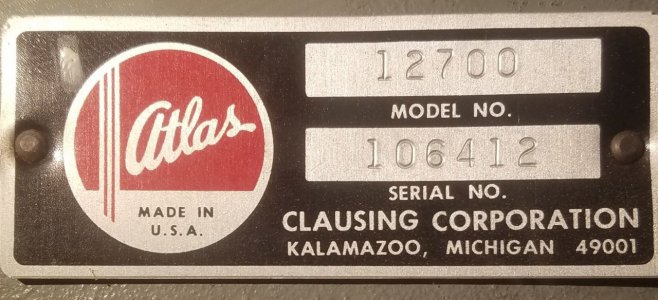

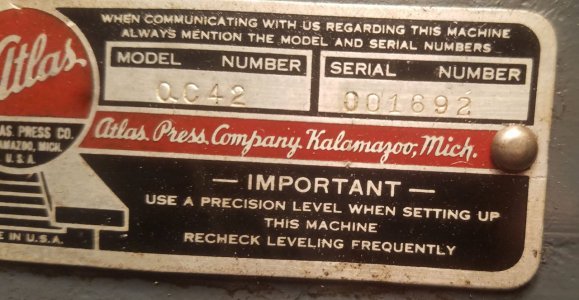

The lathe is one of the last ones made by Atlas, and was saved from a scrap metal yard when the Bureau of Indian Affairs disposed of it. When I got it , I could not close the half nuts because the lead screw was still coated with Cosmoline!

I used my parting tool with a HSS blade for all operations. I had to fight chatter when plunging to get the cut started, and ran the spindle at 164 RPM for all cuts. I was reducing the diameter of the bottom of the groove from 6.525 to 6.275" to accommodate a replacement seal, since the original cross-section seals are no longer available. I plunged to 6.325" and then made a series of plunge cuts, dialing in .100 on the cross-feed. Each plunge cut was about 1/3 the width of the tool. I encountered chatter if I tried to take a bigger bite. I hand-fed across the bottom of the groove and blended the cut to the existing sides of the groove. I followed this up by repeating the process twice. Once to get within .005 of the finished size, and again to the finish diameter. Each time I did a plunge cut, it was in an area where the seal lip would not contact, in case I got a rough finish. I hand-fed every cut, and got a nice finish every time. All cuts were done dry.

I had to flip the piston end-for-end to cut the second groove, but I had dialed in the Buck and did not have to change the setting. It took a long time to do this, but it was a favor for a neighbor, and I was not on the clock!

The lathe is one of the last ones made by Atlas, and was saved from a scrap metal yard when the Bureau of Indian Affairs disposed of it. When I got it , I could not close the half nuts because the lead screw was still coated with Cosmoline!