- Joined

- Feb 7, 2018

- Messages

- 171

After over a year of this project the finish line is slowly creeping into sight and I've decided it's time to put together my pictures and notes from the rebuild of this milling machine to post out to the forum. Admittedly a rebuild like this wouldn't take nearly this long had I been able to focus full time on it but life only allows so much some times. In any case I'm pleased with how it has developed, and I'll now attempt to catch this posting up as quickly as possible to where things actually are in the rebuild process.

Let's go back to the beginning...

I had been on the lookout for a milling machine for a garage machine shop for a while. A knee style mill was most desirable to me and I had narrowed my search down to the Taiwanese 8x30 mill. Grizzly seemed to be the only company still importing these but paying over $4K for just the mill wasn't going to happen which put me into the used market. After about 5 months of looking one showed up on eBay that seemed like a good candidate. It was listed by a machinery seller in the greater LA area so shipping up to Oregon wouldn't be too bad. The machine was listed as a 20 to 30 year old house branded floor model that has never been used. Essentially new, but in need of a rebuild from sitting so long. I made them an offer which was declined, so I made a higher one which was my limit and they also declined that. A month and a half later the machine is still listed so I made yet another offer just a shade above my first low offer and they accepted. On the truck it went up here to Oregon.

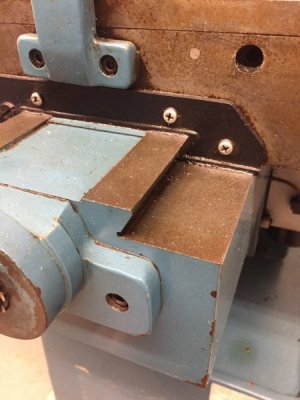

Here's the mill right after I pulled it off the truck. It certainly looked like its sat around for a long time but with no signs of ever being used. They stated that the handles were removed at one point and sold to another customer so there was an obviously long period of time that the machine wasn't even being cranked based on the oil staining marks from where the saddle and knee have been situated.

A coworker helped me get the machine home and unloaded. The engine hoist (crucial!!) worked great but was at it's travel limits lifting it off the trailer so some scooting and swinging was needed to get it all the way.

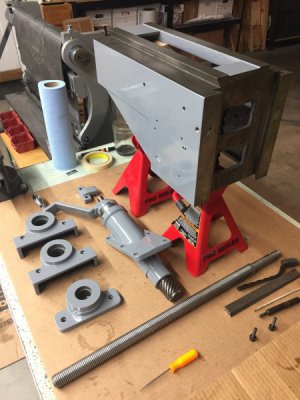

After getting the mill on the floor the route forward was to fully disassemble it for a thorough cleaning and paint job after fixing all the chips in the fairing compound.

Let's go back to the beginning...

I had been on the lookout for a milling machine for a garage machine shop for a while. A knee style mill was most desirable to me and I had narrowed my search down to the Taiwanese 8x30 mill. Grizzly seemed to be the only company still importing these but paying over $4K for just the mill wasn't going to happen which put me into the used market. After about 5 months of looking one showed up on eBay that seemed like a good candidate. It was listed by a machinery seller in the greater LA area so shipping up to Oregon wouldn't be too bad. The machine was listed as a 20 to 30 year old house branded floor model that has never been used. Essentially new, but in need of a rebuild from sitting so long. I made them an offer which was declined, so I made a higher one which was my limit and they also declined that. A month and a half later the machine is still listed so I made yet another offer just a shade above my first low offer and they accepted. On the truck it went up here to Oregon.

Here's the mill right after I pulled it off the truck. It certainly looked like its sat around for a long time but with no signs of ever being used. They stated that the handles were removed at one point and sold to another customer so there was an obviously long period of time that the machine wasn't even being cranked based on the oil staining marks from where the saddle and knee have been situated.

A coworker helped me get the machine home and unloaded. The engine hoist (crucial!!) worked great but was at it's travel limits lifting it off the trailer so some scooting and swinging was needed to get it all the way.

After getting the mill on the floor the route forward was to fully disassemble it for a thorough cleaning and paint job after fixing all the chips in the fairing compound.