Where is everyone locating their scales for the Y axis and how are you orienting them? Face up, down, in, or out?

Same for x as well, though, at the moment, I'm planning on putting it on the backside of of the table. Scale on the moving table, read head on the non moving y axis carriage. Not sure yet on if the face of the scale will point down or back toward column w/added chip gaurd

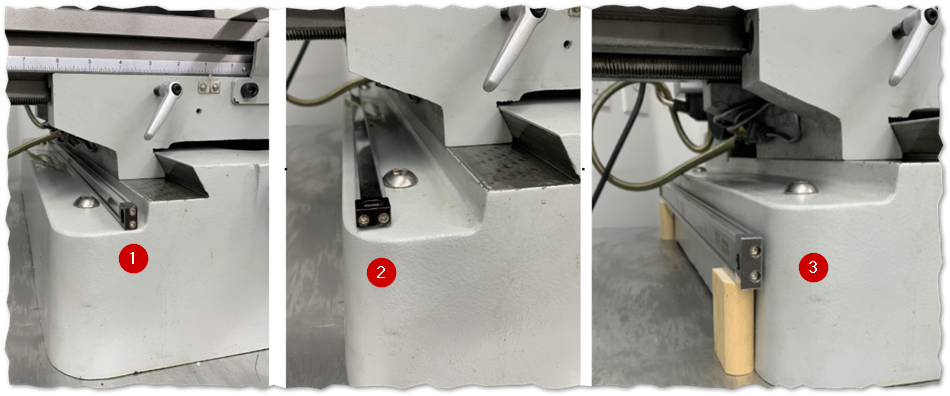

I'm leaning toward option 3, though, seems like a long reach for a bracket to mount to the y axis sled. #3 seems to be the best to stay away from the oozing oil from the ways as well as easiest to protect with some angle iron for chips etc... Not sure how much I need to protect the magnetic scales from oil and chips.

For ref, #1 and #2 is a slim scale As seen, I have enough room to stand it on it's edge in #1 location. Though I got it for the quill location. That one I'm leaving for another day, not sure where/how I plan to integrate it in the head unit.

#3 is the standard body size that holes the magnetic scale scale tape. The actual scale is the same size for both, should have just bought the slim body scales for all axis. The only benefit to the larger scale is the heft in the extrusion that holds it.

Same for x as well, though, at the moment, I'm planning on putting it on the backside of of the table. Scale on the moving table, read head on the non moving y axis carriage. Not sure yet on if the face of the scale will point down or back toward column w/added chip gaurd

I'm leaning toward option 3, though, seems like a long reach for a bracket to mount to the y axis sled. #3 seems to be the best to stay away from the oozing oil from the ways as well as easiest to protect with some angle iron for chips etc... Not sure how much I need to protect the magnetic scales from oil and chips.

For ref, #1 and #2 is a slim scale As seen, I have enough room to stand it on it's edge in #1 location. Though I got it for the quill location. That one I'm leaving for another day, not sure where/how I plan to integrate it in the head unit.

#3 is the standard body size that holes the magnetic scale scale tape. The actual scale is the same size for both, should have just bought the slim body scales for all axis. The only benefit to the larger scale is the heft in the extrusion that holds it.