- Joined

- Jan 20, 2018

- Messages

- 5,913

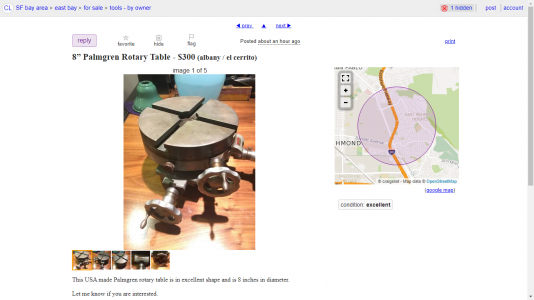

8” Palmgren Rotary Table - tools - by owner - sale

This USA made Palmgren rotary table is in excellent shape and is 8 inches in diameter. Let me know...

sfbay.craigslist.org