- Joined

- Mar 23, 2021

- Messages

- 357

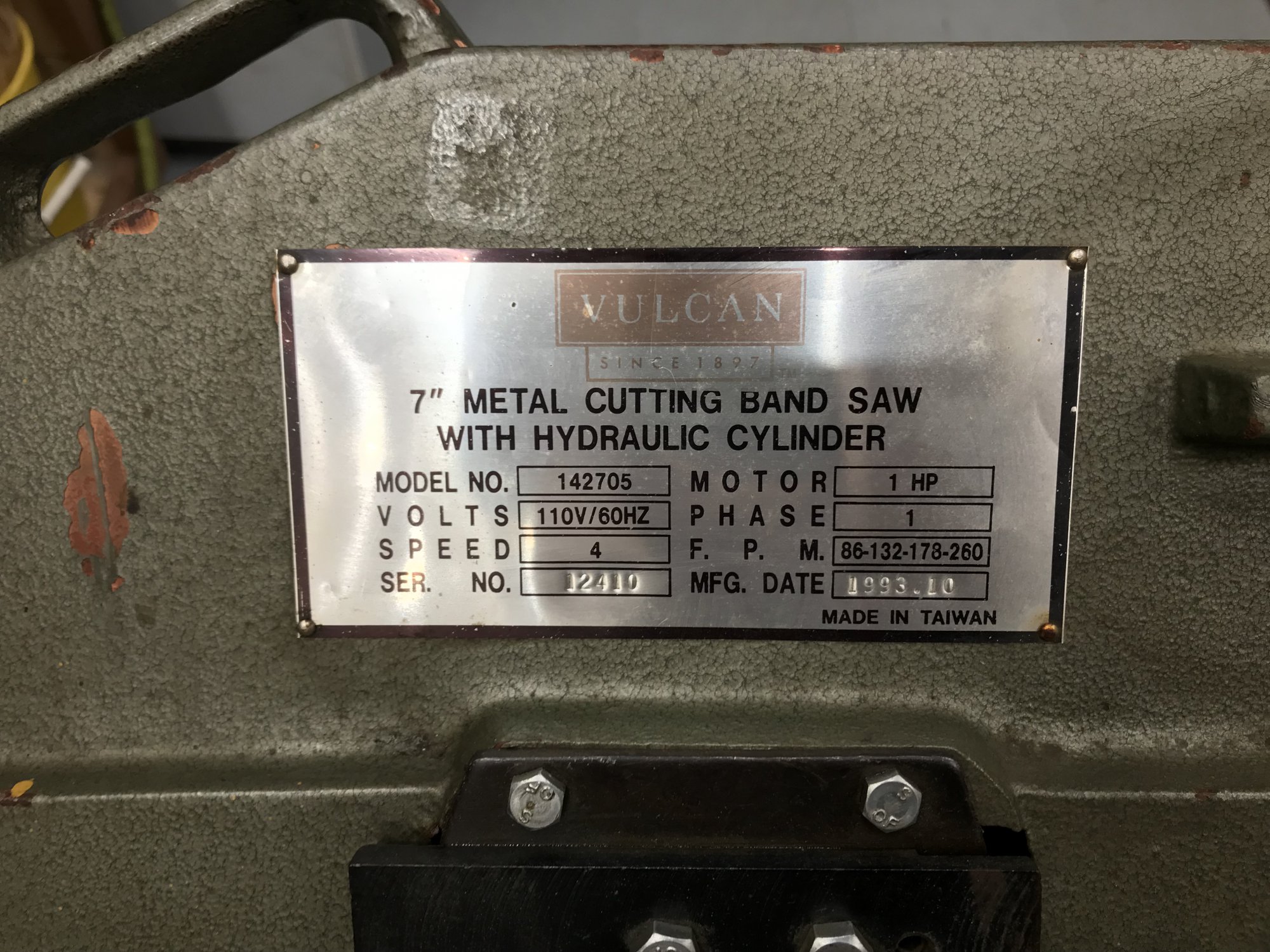

Picked up a 1993 model Vulcan Horizontal Bandsaw. It was local on Craigslist, and the asking price was $250, but it looked pretty rough from the posted photos. Since it was only about 40 minutes away I decided go have a look as one of these has been on my radar for a while now.

As you can see it was used hard and put up dirty! It had sat for almost 20 years since it's last use and the seller (son of deceased father) had just cut the power cable and coolant tubing to separate the machine so it was lighter to load into a cargo trailer. They were going to move it when he decided to sell it instead and it was packed into the front of the trailer with lots of other stuff when I got there.

Unable to even verify a good motor, and since it was covered with lots of old swarf and rust I offered him $150 and he accepted.

After a few days of cleanup and servicing it's turned out to be a very nice machine! The motor runs cool and quiet and all the bearings are still in good shape. The gearbox oil was black but the gears look like new. There's some wear on the top surface of the base between the vise jaws where the operator had apparently been dragging long pieces of channel across if for years and worn some grooves. So far they don't seem to be a problem.

I'm not going to bother with coolant as I don't want the mess in my shop and from my cleanup efforts it's obvious that the coolant carries swarf to a lot of places!

My first cut was on mild steel round stock with the blade that was on the machine. The blade is missing a few teeth and has definitely seen better days (new blades are on the way!), but even so it cuts pretty well. Here's a shot of the first cut and the wafer that I cut off was parallel within .005", not bad!

So overall I'm very happy with this machine since I'm only into it for $150 and some effort!

As you can see it was used hard and put up dirty! It had sat for almost 20 years since it's last use and the seller (son of deceased father) had just cut the power cable and coolant tubing to separate the machine so it was lighter to load into a cargo trailer. They were going to move it when he decided to sell it instead and it was packed into the front of the trailer with lots of other stuff when I got there.

Unable to even verify a good motor, and since it was covered with lots of old swarf and rust I offered him $150 and he accepted.

After a few days of cleanup and servicing it's turned out to be a very nice machine! The motor runs cool and quiet and all the bearings are still in good shape. The gearbox oil was black but the gears look like new. There's some wear on the top surface of the base between the vise jaws where the operator had apparently been dragging long pieces of channel across if for years and worn some grooves. So far they don't seem to be a problem.

I'm not going to bother with coolant as I don't want the mess in my shop and from my cleanup efforts it's obvious that the coolant carries swarf to a lot of places!

My first cut was on mild steel round stock with the blade that was on the machine. The blade is missing a few teeth and has definitely seen better days (new blades are on the way!), but even so it cuts pretty well. Here's a shot of the first cut and the wafer that I cut off was parallel within .005", not bad!

So overall I'm very happy with this machine since I'm only into it for $150 and some effort!