- Joined

- Apr 9, 2023

- Messages

- 264

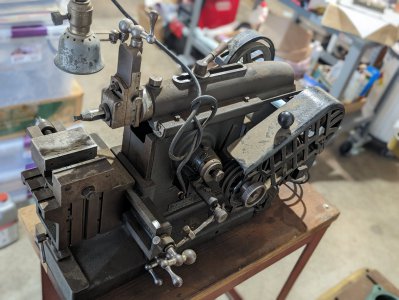

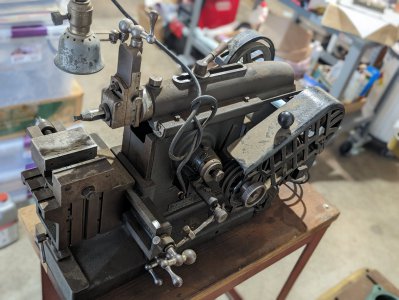

So, I went to buy a lathe...but it seems that I'm not very good at doing that, because I ended up with a shaper instead.

Pictured: Things I've stuffed into the back of my Toyota, Item # 368

This was part of a package deal that included a somewhat-worse-for-wear Clausing 200 that I haven't entirely walked away from, yet; I honestly think the lathe is pretty decent, I just don't trust my own evaluation abilities enough to say whether or not I can bring it fully back up to spec...and I'm not good enough with a lathe to know whether the screw-ups are my own fault or that of the machine. That being said, the seller and I got along pretty well - me not nitpicking and bashing his tooling probably helped - so when I asked, he agreed to sell me this little thing. I think it's in pretty decent shape. See what I did, there?

Pictured: For reference, it's one of these.

I haven't finished fully assessing it, yet, but from what I can tell, it's pretty clean...well, rather, it isn't clean at all because it hasn't run in ten years or so, but it's clean underneath all the grime and dust. Attached are a few shots from when we unloaded it into my still-in-progress and very-crammed-full garage.

PIctured: From the front, including a fun little work light. Gonna have to keep that.

Pictured: Mmmmm...levers...

Pictured: Mmmmm...Japanned cast iron...I think.

Pictured: Not just one, but two intact guards...which is evidently kind of a thing, I'm told.

Pictured: Original motor? Made by Sunlight, via Packard Electric. Gotta look this one up.

Pictured: Markings look pretty clean...and I think the rust-colored stuff is mostly congealed oil, and not actual rust.

Pictured: Surprisingly-good knurling!

Pictured: Last but not least, my favorite part of the machine.

I got what I consider to be a decent deal on it; after checking it out at the seller's shop, I figured I could get it up and running and do a light restore on it and then start making metal shavings in the mellowest, most Bob-Rossiest of all possible ways...but I may not have much work to do on this one, to be honest. Everything seems to be mostly-free and moving - somewhat stiff, granted - and the interior looks clean. There's a bit of light scarring on the top of one way, and the vise jaws have some scratching, and there's not much of a stand included...but it's a pretty clean little machine, overall. I need to look up some history on it and download a manual and learn how to set up the thing before I accidentally break it, and I think I would like some period-correct wrenches for it, because that's something that I am missing: I think I need a 5/16" square or eight-point, 3/8", 1/2" and 7/8" hexes or open-ends, possibly a 7/8" 12-point because of where the vise lockdown bolt is positioned, and the two weird ones...which are 19/32" and 25/32", amazingly. And that many wrenches will need a drawer, and if I have a drawer then I have to have something for the drawer to rest inside-of, which means a stand, and...okay, yeah, this is kind of a project after all.

Anyway, that's what I picked up today; it's the first larger tool that I've bought that I would actually consider "vintage" - my late-80's drill press doesn't count - and I'm already kind of fond of it. Now it just needs a decent lathe and a pint-sized mill to go with it.

Pictured: Things I've stuffed into the back of my Toyota, Item # 368

This was part of a package deal that included a somewhat-worse-for-wear Clausing 200 that I haven't entirely walked away from, yet; I honestly think the lathe is pretty decent, I just don't trust my own evaluation abilities enough to say whether or not I can bring it fully back up to spec...and I'm not good enough with a lathe to know whether the screw-ups are my own fault or that of the machine. That being said, the seller and I got along pretty well - me not nitpicking and bashing his tooling probably helped - so when I asked, he agreed to sell me this little thing. I think it's in pretty decent shape. See what I did, there?

Pictured: For reference, it's one of these.

I haven't finished fully assessing it, yet, but from what I can tell, it's pretty clean...well, rather, it isn't clean at all because it hasn't run in ten years or so, but it's clean underneath all the grime and dust. Attached are a few shots from when we unloaded it into my still-in-progress and very-crammed-full garage.

PIctured: From the front, including a fun little work light. Gonna have to keep that.

Pictured: Mmmmm...levers...

Pictured: Mmmmm...Japanned cast iron...I think.

Pictured: Not just one, but two intact guards...which is evidently kind of a thing, I'm told.

Pictured: Original motor? Made by Sunlight, via Packard Electric. Gotta look this one up.

Pictured: Markings look pretty clean...and I think the rust-colored stuff is mostly congealed oil, and not actual rust.

Pictured: Surprisingly-good knurling!

Pictured: Last but not least, my favorite part of the machine.

I got what I consider to be a decent deal on it; after checking it out at the seller's shop, I figured I could get it up and running and do a light restore on it and then start making metal shavings in the mellowest, most Bob-Rossiest of all possible ways...but I may not have much work to do on this one, to be honest. Everything seems to be mostly-free and moving - somewhat stiff, granted - and the interior looks clean. There's a bit of light scarring on the top of one way, and the vise jaws have some scratching, and there's not much of a stand included...but it's a pretty clean little machine, overall. I need to look up some history on it and download a manual and learn how to set up the thing before I accidentally break it, and I think I would like some period-correct wrenches for it, because that's something that I am missing: I think I need a 5/16" square or eight-point, 3/8", 1/2" and 7/8" hexes or open-ends, possibly a 7/8" 12-point because of where the vise lockdown bolt is positioned, and the two weird ones...which are 19/32" and 25/32", amazingly. And that many wrenches will need a drawer, and if I have a drawer then I have to have something for the drawer to rest inside-of, which means a stand, and...okay, yeah, this is kind of a project after all.

Anyway, that's what I picked up today; it's the first larger tool that I've bought that I would actually consider "vintage" - my late-80's drill press doesn't count - and I'm already kind of fond of it. Now it just needs a decent lathe and a pint-sized mill to go with it.