- Joined

- Oct 16, 2017

- Messages

- 341

This took me two days!

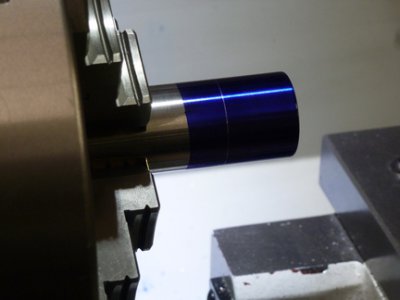

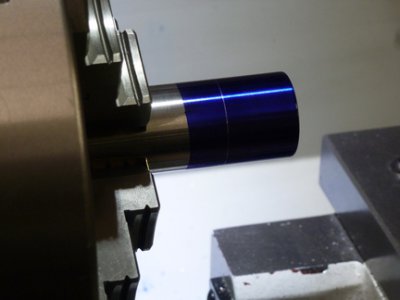

I built a barrel vice (they're expensive at Brownells):

followed by an action wrench to fit the integral Picatinny rail:

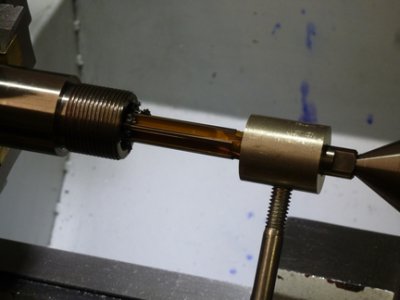

After carefully centering the bore with a PTG Grizzly rod, 4 jaw and outboard spider I found the barrel shank and bore to be running fairly concentric:

View attachment P1000492.mp4

Tenon Layout:

Thread profile and final tenon length:

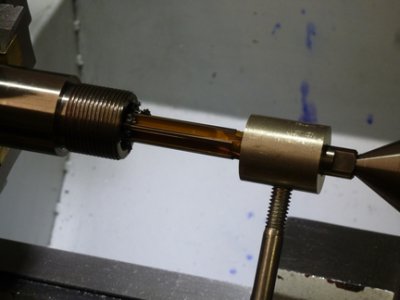

Threading w/ carbide insert:

Finished thread (no lead in thread removal required with Impact action):

Bolt nose recess cut with a carbide insert boring bar:

Cutting the chamber with PTG live pilot finishing reamer (head stock aligned dead center):

Chamber final depth checked w/ Clymer Go-Gauge + 0.003" for barrel make up:

Checking final chamber run out (too much, we'll see):

View attachment P1000505.mp4

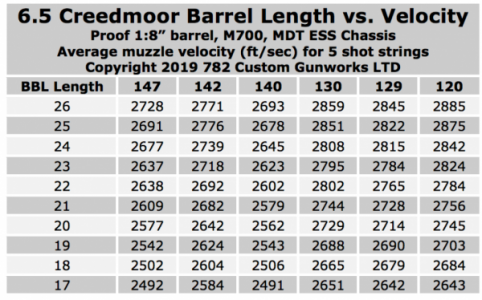

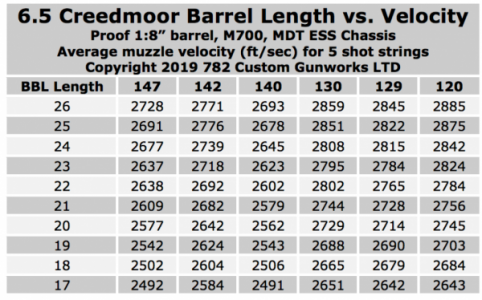

Barrel installed (25" from muzzle to breach face based on max velocity vs. barrel length for 142gn SMK test performed by rifleshooter.com):

I built a barrel vice (they're expensive at Brownells):

followed by an action wrench to fit the integral Picatinny rail:

After carefully centering the bore with a PTG Grizzly rod, 4 jaw and outboard spider I found the barrel shank and bore to be running fairly concentric:

View attachment P1000492.mp4

Tenon Layout:

Thread profile and final tenon length:

Threading w/ carbide insert:

Finished thread (no lead in thread removal required with Impact action):

Bolt nose recess cut with a carbide insert boring bar:

Cutting the chamber with PTG live pilot finishing reamer (head stock aligned dead center):

Chamber final depth checked w/ Clymer Go-Gauge + 0.003" for barrel make up:

Checking final chamber run out (too much, we'll see):

View attachment P1000505.mp4

Barrel installed (25" from muzzle to breach face based on max velocity vs. barrel length for 142gn SMK test performed by rifleshooter.com):

Last edited: