Hello,

I have been getting my 1228 dialed in and getting used to using it and I came across a question I hope you guys can help me with.

I have a Seco CFZR 0632802DRB cutoff tool and, when I ordered my lathe, I got the AXA holder that accommodates the 5/8" shank. No problems there.

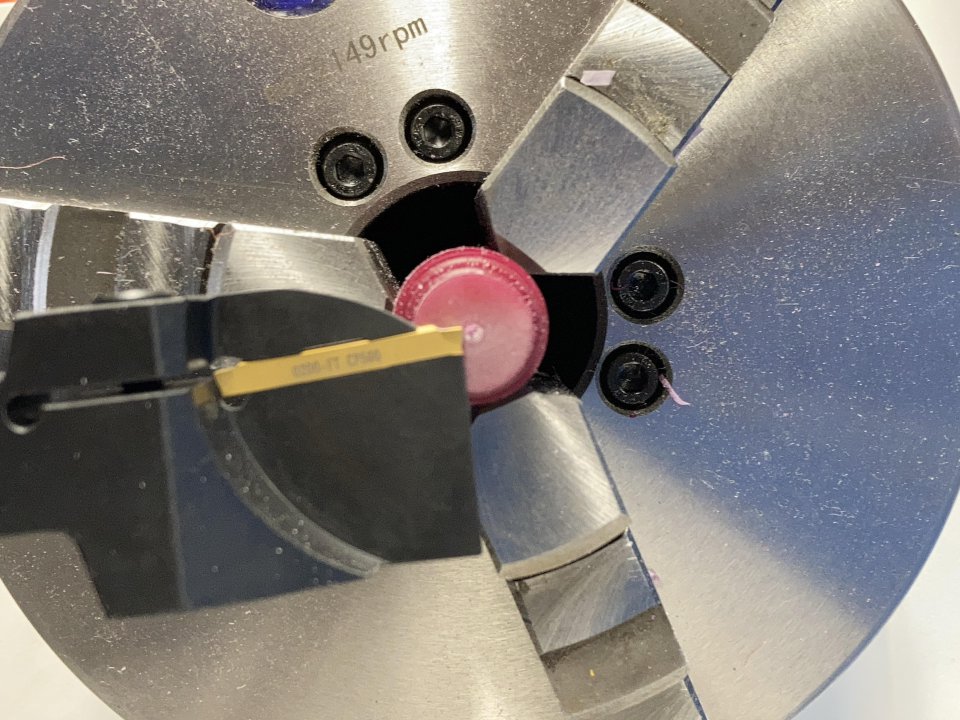

When I tried using it, it seemed that the insert was above the center line of the lathe. I have included a pic below. The problem is I believe I have the toolholder all the way down. In fact, I think it is actually sitting on the compound, not being supported at all by the screw on the tool holder.

So my questions are this:

1. Am I correct that that is too high and the cutting edge should be lower?

2. Is there a way to shim it or something to tilt the tool downward a bit?

I'm really hoping there is a solution because I was lead to believe there would be no issues using it and I really think it is just about perfect for what I want and would hate to have it not be usable.

Thanks!

I have been getting my 1228 dialed in and getting used to using it and I came across a question I hope you guys can help me with.

I have a Seco CFZR 0632802DRB cutoff tool and, when I ordered my lathe, I got the AXA holder that accommodates the 5/8" shank. No problems there.

When I tried using it, it seemed that the insert was above the center line of the lathe. I have included a pic below. The problem is I believe I have the toolholder all the way down. In fact, I think it is actually sitting on the compound, not being supported at all by the screw on the tool holder.

So my questions are this:

1. Am I correct that that is too high and the cutting edge should be lower?

2. Is there a way to shim it or something to tilt the tool downward a bit?

I'm really hoping there is a solution because I was lead to believe there would be no issues using it and I really think it is just about perfect for what I want and would hate to have it not be usable.

Thanks!