I have had this HF 4x6 probably since 2007 or so. Right when I got it, I discarded the flimsy folding "legs", and made a wood base for it. I later added a hydraulic piston to replace the spring, and for the most part that has been it until last fall (2013). But now that I am starting to do/learn more welding, and cutting metal more often, I decided to "attack" the many weak points, including the over-heating motor (which is obviously too small for the job - some of these actually catch on fire!). I also wanted to add cooling to it, so I decided to do a complete overhaul of the bandsaw. This took about 3 months (on and off), and several purchases spread over the 3 months (I am on a budget, like most people), but now that it is 99% complete, I wanted to share my project.

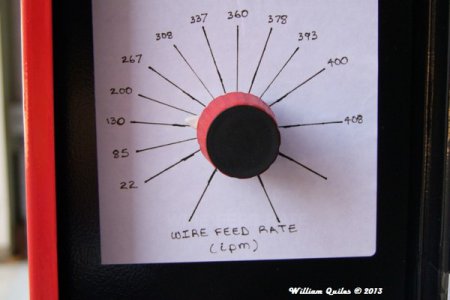

I of course over-built the base/stand, but I figured I can fairly easily re-use the base with another bandsaw if this one totally needs a replacement later on. I used 1-1/4" (1/8" wall) squared hot rolled steel, and 1-1/4" (1/4" wall) angle iron for the top. Everything was MIG welded with my MIG200 using 0.035" solid wire with about 25cfpm of 75%/35% shielding gas.

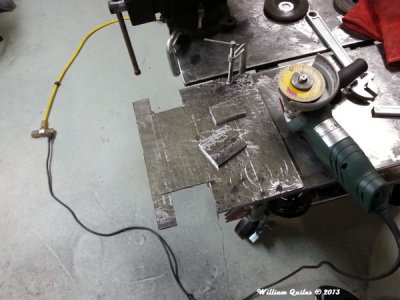

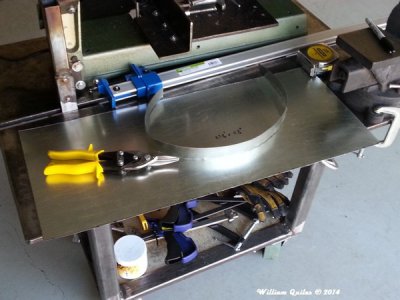

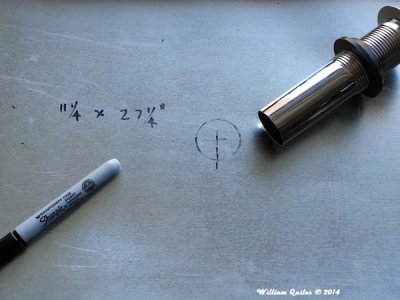

Here is the "before" picture - I am checking the size of the new top (notice size of stock motor):

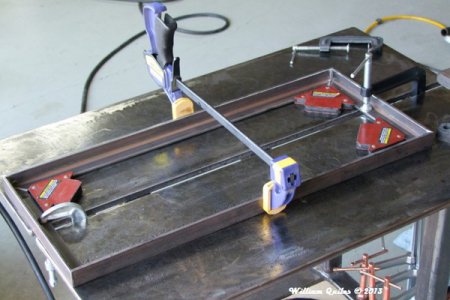

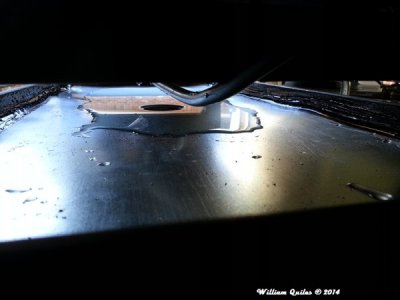

Here is the "raw" new welded base:

Previous wood base next to new base:

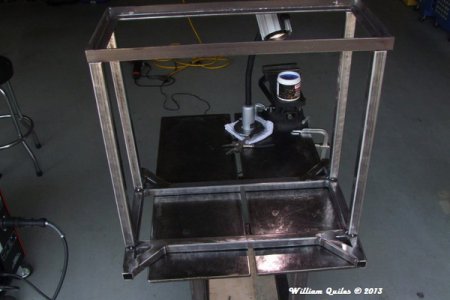

Preliminary picture showing the hydraulic piston in place:

Finished bandsaw after all mods:

- new steel base (2 coats of flat black paint)

- replaced 1/3 HP (Chinese rating!) SP motor with USA-made, Baldor 3/4HP 3P motor (using TECO VFD for variable speed and safety switch)

- new clamping "system" (more on that later)

- making new "arm" for hydraulic system

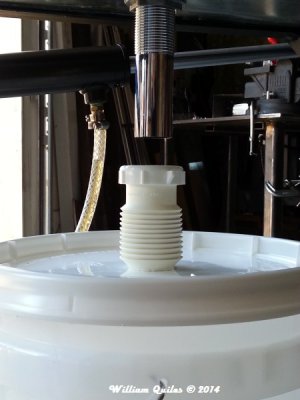

- adjustable coolant system (running

A little bit more background on the "why" I upgraded the bandsaw with a hydraulic piston, since this is a popular mod for 4x6 bandsaws .....

The stock bandsaw comes with this stupid spring, which is meant to "try" to counterbalance the weight of the horizontal mass, in order to "try" to control how fast that mass (and thus the blade) moves down. You basically have a screw that you move in and out to change the tension on the spring against the moving mass. The problem is that it is nearly impossible to get the spring to perfectly balance the weight AND control how fast the whole assembly moves down. Bottom line: the spring does not allow fine-tuning the speed to accommodate a variety of materials.

The hydraulic piston controls how fast the whole assembly moves down, by letting hydraulic fluid slowly escape via the adjustment valve. You can also completely stop the movement at any position along the travel angle, which comes handy to align the cut with the blade. This adjustment made available by the valve is "very" wide, thus you have almost infinite control on how fast the blade moves down into the work, so that you can adjust to the material type, thickness, number of pieces being cut, etc.. This flexibility is why ALL of the larger bandsaws have a hydraulic piston on them. The 4x6 don't have one (and have the stupid spring) not because it is not needed, but because cost - it is the only way to keep the saw cheap and available to the hobby machinist. Here are two Grizzly bandsaws showing a hydraulic piston on them:

These videos I took 3-years ago, but clearly show the adjustment range I have in my bandsaw:

- Video 1: This is the fastest down travel, fully opening the valve very fast. It you watch closely, you can clearly see the speed increasing as I open the valve:

http://www.youtube.com/watch?v=c6imAX3KnQ4

- Video 2: This is a slightly slower down travel speed. You could probably cut wood this fast, or a thin walled metal part:

http://www.youtube.com/watch?v=NEVeIn5Bv2Y

- Video 3: This is an example of a very slow, controlled downward speed obtainable with the hydraulic piston. This range of speed (or a tad faster) is typically what I use when cutting most metals:

http://www.youtube.com/watch?v=u-TpwCDG_5k

If you look at the 4x6 Yahoo group, you will see that this hydraulic conversion is one of the most popular upgrades. Lots of ingenuity in how folks have added a hydraulic piston to their 4x6 bandsaw, and it was from that group that I got the idea to do mine back 3 years ago.

Will

I of course over-built the base/stand, but I figured I can fairly easily re-use the base with another bandsaw if this one totally needs a replacement later on. I used 1-1/4" (1/8" wall) squared hot rolled steel, and 1-1/4" (1/4" wall) angle iron for the top. Everything was MIG welded with my MIG200 using 0.035" solid wire with about 25cfpm of 75%/35% shielding gas.

Here is the "before" picture - I am checking the size of the new top (notice size of stock motor):

Here is the "raw" new welded base:

Previous wood base next to new base:

Preliminary picture showing the hydraulic piston in place:

Finished bandsaw after all mods:

- new steel base (2 coats of flat black paint)

- replaced 1/3 HP (Chinese rating!) SP motor with USA-made, Baldor 3/4HP 3P motor (using TECO VFD for variable speed and safety switch)

- new clamping "system" (more on that later)

- making new "arm" for hydraulic system

- adjustable coolant system (running

A little bit more background on the "why" I upgraded the bandsaw with a hydraulic piston, since this is a popular mod for 4x6 bandsaws .....

The stock bandsaw comes with this stupid spring, which is meant to "try" to counterbalance the weight of the horizontal mass, in order to "try" to control how fast that mass (and thus the blade) moves down. You basically have a screw that you move in and out to change the tension on the spring against the moving mass. The problem is that it is nearly impossible to get the spring to perfectly balance the weight AND control how fast the whole assembly moves down. Bottom line: the spring does not allow fine-tuning the speed to accommodate a variety of materials.

The hydraulic piston controls how fast the whole assembly moves down, by letting hydraulic fluid slowly escape via the adjustment valve. You can also completely stop the movement at any position along the travel angle, which comes handy to align the cut with the blade. This adjustment made available by the valve is "very" wide, thus you have almost infinite control on how fast the blade moves down into the work, so that you can adjust to the material type, thickness, number of pieces being cut, etc.. This flexibility is why ALL of the larger bandsaws have a hydraulic piston on them. The 4x6 don't have one (and have the stupid spring) not because it is not needed, but because cost - it is the only way to keep the saw cheap and available to the hobby machinist. Here are two Grizzly bandsaws showing a hydraulic piston on them:

These videos I took 3-years ago, but clearly show the adjustment range I have in my bandsaw:

- Video 1: This is the fastest down travel, fully opening the valve very fast. It you watch closely, you can clearly see the speed increasing as I open the valve:

http://www.youtube.com/watch?v=c6imAX3KnQ4

- Video 2: This is a slightly slower down travel speed. You could probably cut wood this fast, or a thin walled metal part:

http://www.youtube.com/watch?v=NEVeIn5Bv2Y

- Video 3: This is an example of a very slow, controlled downward speed obtainable with the hydraulic piston. This range of speed (or a tad faster) is typically what I use when cutting most metals:

http://www.youtube.com/watch?v=u-TpwCDG_5k

If you look at the 4x6 Yahoo group, you will see that this hydraulic conversion is one of the most popular upgrades. Lots of ingenuity in how folks have added a hydraulic piston to their 4x6 bandsaw, and it was from that group that I got the idea to do mine back 3 years ago.

Will

Last edited: