-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4-Way Tool Post

- Thread starter rfresh747

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,087

Many commercial boring bars have a flat on the top for set screws....

- Joined

- Sep 25, 2014

- Messages

- 1,149

You can very easily make a holder. If you want to be fancy get some square stock (such as key stock) grip it in the holder and line it up parallel to the ways. It need not be perfectly aligned, but for the sake of doing a nice job, make it as good as you can. Put your drill chuck in the spindle and drill a hole in the square stock length wise. Remove and add some set screws or split it with a hacksaw.

For the set screws, you can do that with the square stock still in the 4 way, just turned 90.

Of course you can just stick the boring bar in the 4 way, add some packing (flat bar scraps underneath and pinch down on the bar. It works even better if you bar has some flats, but it still works on round bar. Go easy on the cuts.

For the set screws, you can do that with the square stock still in the 4 way, just turned 90.

Of course you can just stick the boring bar in the 4 way, add some packing (flat bar scraps underneath and pinch down on the bar. It works even better if you bar has some flats, but it still works on round bar. Go easy on the cuts.

- Joined

- Feb 2, 2013

- Messages

- 3,908

Hi rfresh,

if you have small enough shanks on your boring bars, you could make a simple holder.

simply take a piece of square stock and drill and ream the desired ID and slit the assembly longitudinally

insert a boring bar into the newly constructed holder and insert into the toolpost with the slit facing to the outside

the slit in the holder will clamp down as the clamping set screws are tightened and prevent the boring bar from rotating.

another simple fix is to grind a flat on the boring bar, on the top surface of the shank for the sets crews to tighten against

if you have small enough shanks on your boring bars, you could make a simple holder.

simply take a piece of square stock and drill and ream the desired ID and slit the assembly longitudinally

insert a boring bar into the newly constructed holder and insert into the toolpost with the slit facing to the outside

the slit in the holder will clamp down as the clamping set screws are tightened and prevent the boring bar from rotating.

another simple fix is to grind a flat on the boring bar, on the top surface of the shank for the sets crews to tighten against

- Joined

- Dec 20, 2012

- Messages

- 9,422

The problem with adapters is that they take up a lot of space and you may, or may not, be able to get the tip of the tool above centerline as it should be. Smithy makes this one:

Little Machine Shop sells this one:

Ideally, you will have 3/8" shank boring bars so you have some space to fit the bar and adapter in the slot of the 4 way post and still have room to shim it 0.005 - 0.010" above centerline. You may have to make an adapter as the guys suggested.

Little Machine Shop sells this one:

Ideally, you will have 3/8" shank boring bars so you have some space to fit the bar and adapter in the slot of the 4 way post and still have room to shim it 0.005 - 0.010" above centerline. You may have to make an adapter as the guys suggested.

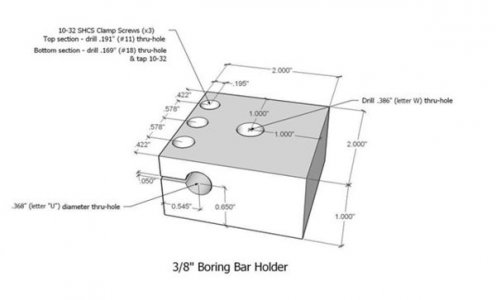

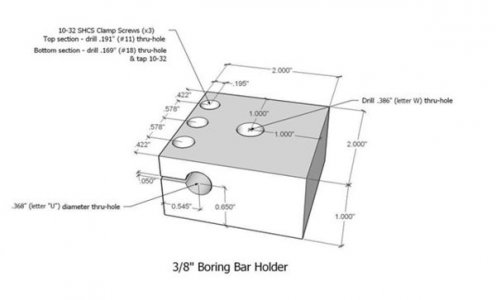

Just yesterday I made a dedicated tool post for holding a 3/8” boring bar for my 7x12 out of one lonely piece of (surface) rusted 2”x 2”x 1” thick steel flat bar I’ve had sitting around here forever (I knew I would find a use for it eventually). No idea what grade of steel, but cut/drilled pretty easily.

First, placed it in 4-jaw & faced off both sides .020” to get rid of surface rust & ensure both contact surfaces were flat (top/bottom). Then drilled the center hole for the mounting stud ….in my case .386” or letter “W”.

Swapped the 4-jaw for my 3-jaw to hold drill bit(s) (I know, not the right way to do it) & mounted the “new” tool post to compound. Once it was squared up with lathe axis & in correct position, tightened it down & drilled the hole for boring bar in 3 steps after center drilling - 5/32”, 9/32” & finally letter W. I was initially just going to simply advance the work into drill bit using the carriage hand wheel, but didn’t like how much stress/torque was being exerted on lead screw, so came up with this idea instead (see photo below): used my tailstock w/drill chuck (jaws fully retracted) placed against backside of block, tightened TS down & advanced the quill to push carriage/tool post into drill bit. Worked like a charm! Way easier on my little machine & with the drill chuck tight against work piece, it kept the work square & prevented it from wanting to rotate/twist. Only went about 3/8” - ½” at a time starting with 5/32 bit, then switch to next size, then final size. Took a little while, but ended up coming out perfect.

All that was needed now was to cut the relief slot (which I did with a hacksaw) & drill/tap three 10-32 holes for clamp screws. Bit of de-burring & good to go.

Certainly won’t win any “project of the month” awards, but it’s an easy, alternate option for you

Hope this helps!

First, placed it in 4-jaw & faced off both sides .020” to get rid of surface rust & ensure both contact surfaces were flat (top/bottom). Then drilled the center hole for the mounting stud ….in my case .386” or letter “W”.

Swapped the 4-jaw for my 3-jaw to hold drill bit(s) (I know, not the right way to do it) & mounted the “new” tool post to compound. Once it was squared up with lathe axis & in correct position, tightened it down & drilled the hole for boring bar in 3 steps after center drilling - 5/32”, 9/32” & finally letter W. I was initially just going to simply advance the work into drill bit using the carriage hand wheel, but didn’t like how much stress/torque was being exerted on lead screw, so came up with this idea instead (see photo below): used my tailstock w/drill chuck (jaws fully retracted) placed against backside of block, tightened TS down & advanced the quill to push carriage/tool post into drill bit. Worked like a charm! Way easier on my little machine & with the drill chuck tight against work piece, it kept the work square & prevented it from wanting to rotate/twist. Only went about 3/8” - ½” at a time starting with 5/32 bit, then switch to next size, then final size. Took a little while, but ended up coming out perfect.

All that was needed now was to cut the relief slot (which I did with a hacksaw) & drill/tap three 10-32 holes for clamp screws. Bit of de-burring & good to go.

Certainly won’t win any “project of the month” awards, but it’s an easy, alternate option for you

Hope this helps!

Last edited:

- Joined

- Sep 29, 2014

- Messages

- 2,102

Mill or grind a flat on the bottom of the boring bar.