- Joined

- Mar 20, 2014

- Messages

- 418

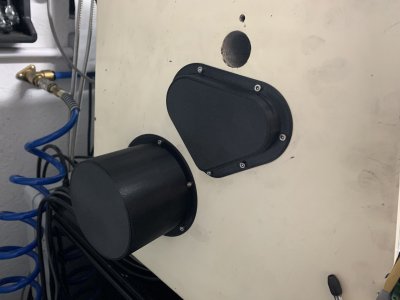

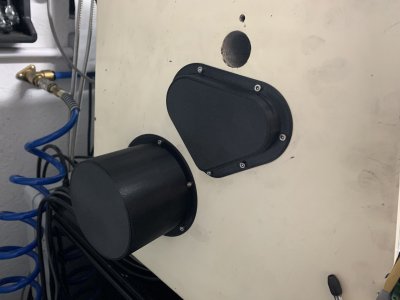

I designed and 3d printed two covers for the lathe change gear case, as I’d had two cut two holes in it to accommodate the servo and encoder on my ELS install:

And I also designed a thread dial indicator. My lathe never had one (it’s metric), but it changing over to the ELS has meant the lathe takes longer (there‘s less drag due to the lack of change gears) to come to a stop, and I have to leave the half nuts engaged. It makes stopping in the thread relief a bit hit and miss some times. After mentioning this in the ELS thread, I was advised to look at Oxtools video on making metric threads in on an imperial lathe. He uses the dial on his lathe to resync the the carriage to the leadscrew after he disengages it prior to stopping the lathe, reversing it and then re-engaging the half nuts when the relevant marks line up.

So I’m giving this a go. I believe I only need one mark for this:

And I also designed a thread dial indicator. My lathe never had one (it’s metric), but it changing over to the ELS has meant the lathe takes longer (there‘s less drag due to the lack of change gears) to come to a stop, and I have to leave the half nuts engaged. It makes stopping in the thread relief a bit hit and miss some times. After mentioning this in the ELS thread, I was advised to look at Oxtools video on making metric threads in on an imperial lathe. He uses the dial on his lathe to resync the the carriage to the leadscrew after he disengages it prior to stopping the lathe, reversing it and then re-engaging the half nuts when the relevant marks line up.

So I’m giving this a go. I believe I only need one mark for this: