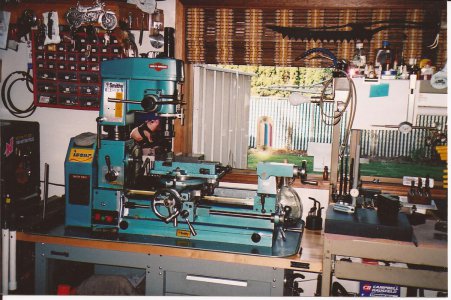

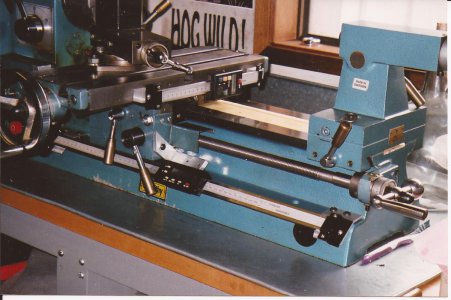

Several months ago I bought an older, 1992, Smithy in good shape with a bunch of tooling. Just got it set up and tested it last weekend. Seemed really noisy, the lathe and especially the mill. I did some disassembly, lubed the gears for the milling head and added oil to the headstock reservoir per instructions which leave something to be desired.

Anyway, I enter my shop today to see oil has started to seep out from under the machine. Is this normal for these critters? My first experience with one so I'm wondering if they are just on the messy side, and noisy? My only experience so far is with a south bend lathe that I've had for about 10 years. Quiet and clean with that.

Any input is appreciated.

Anyway, I enter my shop today to see oil has started to seep out from under the machine. Is this normal for these critters? My first experience with one so I'm wondering if they are just on the messy side, and noisy? My only experience so far is with a south bend lathe that I've had for about 10 years. Quiet and clean with that.

Any input is appreciated.