- Joined

- Apr 8, 2013

- Messages

- 2,021

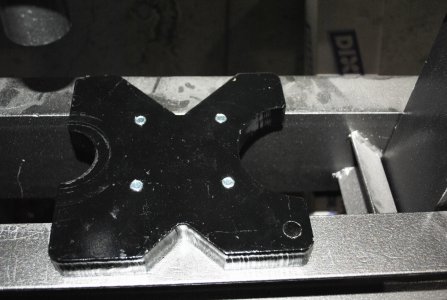

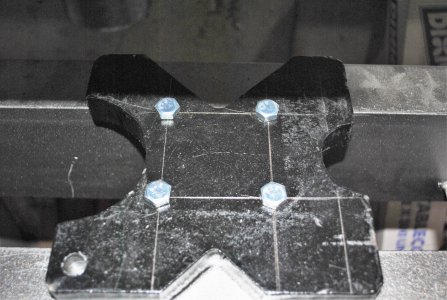

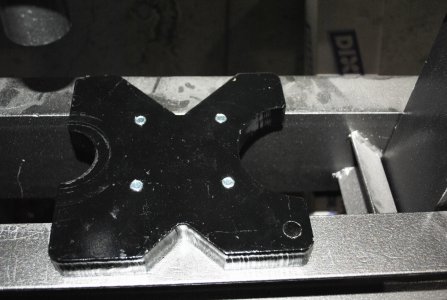

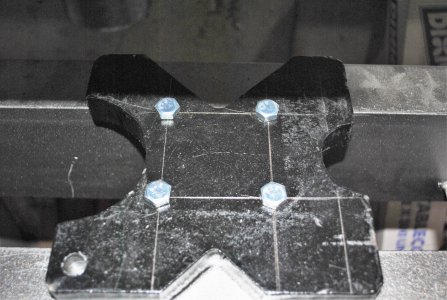

I thought I posted this already but I don't see it. After the press plates fell thru the space between the beams on my Harbor Freight Press I decided to tap the plates for some bolts sticking out the bottom. They're spaced to prevent the plates from moving far enough to fall thru the hole and squash my tootsies.