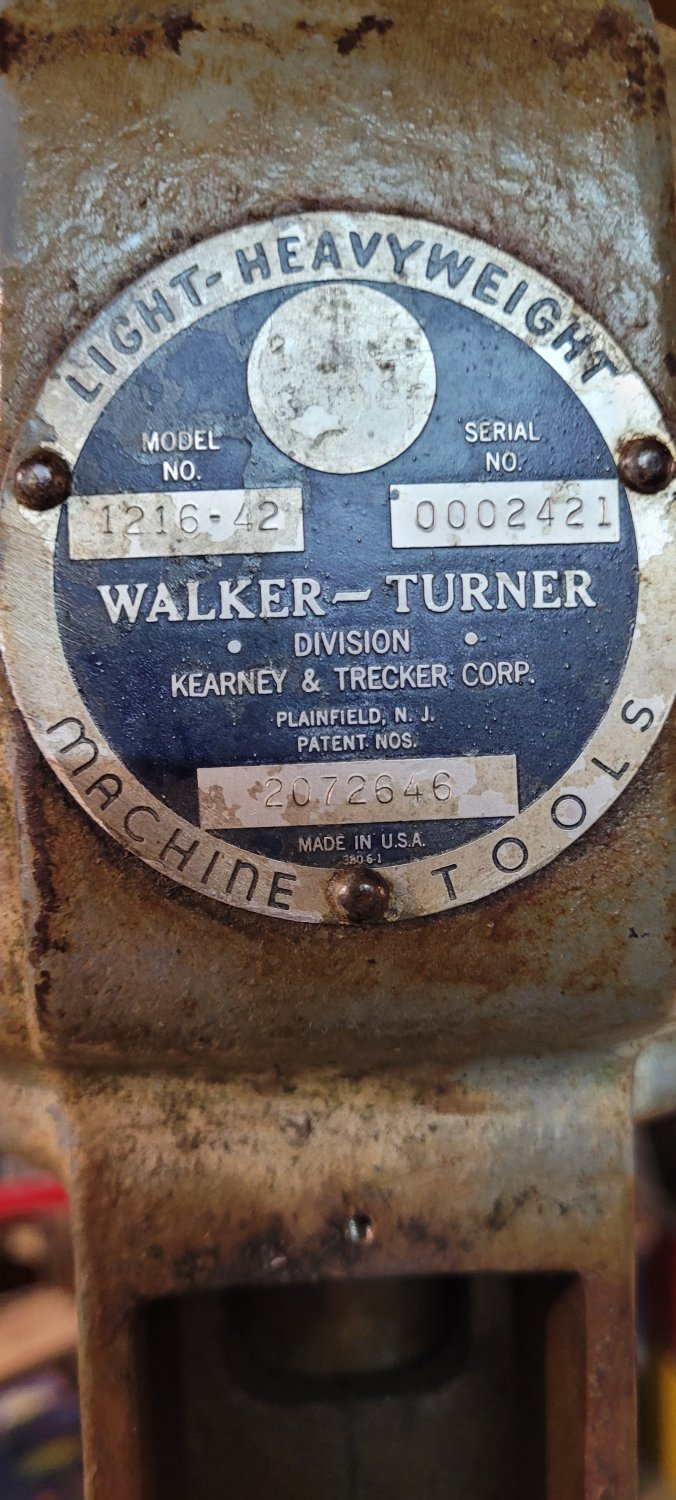

Before I jump onto the tangent.... It's not even done yet, and I'm jealous of that drill press already. That's gonna serve you well.

Oh I would have put tailstock support in there but I don't have a live center thats big enough.

If you're doing stuff like that where you know it's not "fine" how it is.... But you're pretty sure it's "fine" just how it is... And you're almost always right... And it's almost always fine...

Stick a piece of bar in the tail stock drill chuck. Or put a live or dead center inside the "hole" even though it's not ever going to touch. Slide the tailstock up close, so that A, something is "inside" the hole to catch it if it falls, and B, a larger portion, the bearing housing on a live center, the drill chuck body, anything larger than the hole is "close". How close? Well how deep are the chuck jaws? Let's say that's one inch "deep" in the lathe chuck jaws. Whatever is "blocking" would be somewhat less than an inch away from the part.

It will not prevent anything from going south, or true up any machine work, but IF, and ONLY if something doesn't work out, the part can not fall. It can't get out of the chuck jaws on one end, and it can't get over the bar, undersized center, whatever is on the other end. You "might" damage (probably scratch) a drill chuck or a center that way, but that's a lot easier to recover from than having a full on collision with the bed ways.

Did I mention I'm a little jealous of that drill press? Even as bad as that pitting looks, there's a lot of bearing surface left. It's gonna come out nice.