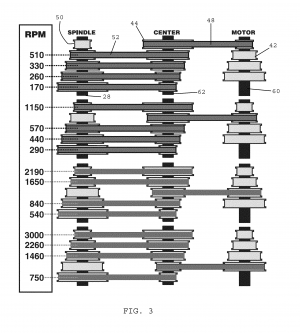

Umm.. I know I can figure out the RPM from any combination if I work through the known sizes, and the motor RPM.

A chart like that is supposed to save one the labour of going through all that every time - a handy quick lookup.

The chart must assume some kind of motor RPM at the start of all this, no??

Right now I am still gaming the thing to death trying to tease out the logic of what the numbers mean, and how they arrive at the RPM.

and .. feeling a bit stooooopid while I am at it. C'mon Graham, we are better than that, aren't we??

[Edit]

If we assume the 5-pulley cones are identical, and that the 4-pulley cone on the motor drive has the same sizes as the first 4 of the bigger cone, then there are 16 relationships that deliver a known RPM. If we let the motor shaft speed be m, and the pulley sizes be A, B, C, D, E smallest to biggest, we have six unknowns, with some that cancel.

e.g. The third set (2190, 1650, 840, 540) are all driven by same pulley size C on motor shaft and centre shaft with ratio 1:1

Thus we know [D/B] * m = 1650

.. and [B/D] * m = 840

.. and so on

It may be possible to quickly tease out m, but one has to fix at least one pulley real size to get at all the others. Otherwise, we only can know them by their relative ratios. We can forcibly set the smallest value to 1, which helps.

OR..

we can just ask

@FOMOGO is he knows which lathe it came from (Draper ??)

[End edit]