Hi

I have a 14x40 optimum lathe 2005. I had bought the lathe around 2012 and has performed great. I went to change the headstock oil and saw A problem with the bearings so I removed the spindle. After removing the spindle I noticed the bearings didn’t look as they should. Races had wear marks where rollers ran, and rollers and races had evidence of contamination at some point.

The oiling system on these lathes is garbage in my opinion. Splash system get throw into holes for spindle Bearing and drips to lube Bearings. Well the channel the oil rides allow sediment to settle in channel which is the supply for the headstock bearings. there is no filtering of the sort and you can see debris settled in areas of the channel. No good

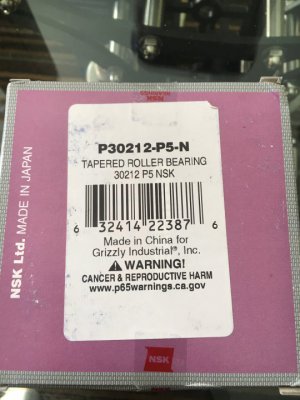

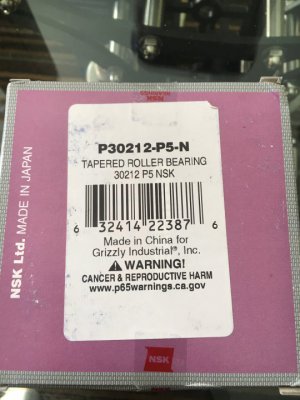

So I was on a mission to find replacement replacement spindle bearings. Original bearings are a no name DRZ 30212/p5 and a 30210/p5 tapered bearing. I did a bunch of searching And surprisingly grizzly tools had the replacements nsk p5 rating bearings for under 200 dollars for both delivered. I found others but the uncertainty of eBay sellers and counterfeit bearings I went with the grizzly bearings. Came in two days was happy with the deal.

Bearings came in nsk sealed boxes with nsk tape sealing the boxes. My first observation was the nsk box has made in Japan good. But grizzly has their sticker on one side with the part number and their logo and it says made in China for grizzly industry.

what the heck which one is it??? Then I opened the boxes. Bearings are in a sealed bag then the bearing was wrapped in another plastic wrap. Looking at the bearings and races their are no p5 ratings on either. the bearings numbers have a J at the end which I thought I read somewhere is a wheel bearing designation??

My problem is the uncertainty. I only want to do this one time with quality materials. What do you all think is this a standard wheel bearing or they just don’t go the extra step and mark the p5 rating anymore. The originals had the marking

I have a 14x40 optimum lathe 2005. I had bought the lathe around 2012 and has performed great. I went to change the headstock oil and saw A problem with the bearings so I removed the spindle. After removing the spindle I noticed the bearings didn’t look as they should. Races had wear marks where rollers ran, and rollers and races had evidence of contamination at some point.

The oiling system on these lathes is garbage in my opinion. Splash system get throw into holes for spindle Bearing and drips to lube Bearings. Well the channel the oil rides allow sediment to settle in channel which is the supply for the headstock bearings. there is no filtering of the sort and you can see debris settled in areas of the channel. No good

So I was on a mission to find replacement replacement spindle bearings. Original bearings are a no name DRZ 30212/p5 and a 30210/p5 tapered bearing. I did a bunch of searching And surprisingly grizzly tools had the replacements nsk p5 rating bearings for under 200 dollars for both delivered. I found others but the uncertainty of eBay sellers and counterfeit bearings I went with the grizzly bearings. Came in two days was happy with the deal.

Bearings came in nsk sealed boxes with nsk tape sealing the boxes. My first observation was the nsk box has made in Japan good. But grizzly has their sticker on one side with the part number and their logo and it says made in China for grizzly industry.

what the heck which one is it??? Then I opened the boxes. Bearings are in a sealed bag then the bearing was wrapped in another plastic wrap. Looking at the bearings and races their are no p5 ratings on either. the bearings numbers have a J at the end which I thought I read somewhere is a wheel bearing designation??

My problem is the uncertainty. I only want to do this one time with quality materials. What do you all think is this a standard wheel bearing or they just don’t go the extra step and mark the p5 rating anymore. The originals had the marking