- Joined

- Dec 19, 2018

- Messages

- 130

So thought I would post here as this might be helpfull to guys with benchtop lathes in generall. I originally posted over in the Grizz sub forum but not really getting a lot of exposure. Seeing as how most all the china benchtop lathes are manufactured very similar, i'm thinking this might be of interest to a more general lathe crowd.

I have the Grizz 11x29 and it's almost identical to the 10x22 ( as far as component drivetrain design ). Thus far i've upgraded to a 2hp 1500W VFD system, and let me be clear what a HUGE improvement in low end torque. My previous min speed was 150 rpm's and that "can" be challenging with threading in blind bores or up against shoulders. With my VFD, and my belt configuration set at min speed I can get down to 41 rpm and that's VERY helpful for threading in certain circumstances where you don't have a large "runoff" area of material. The VFD spindle braking is almost instant so threading meteric (having to keep the half nut engaged) is far less risk of a crash. I also added a magnetic scale DRO system and that goes without saying. NO MORE tedious counting the dials ! Here's a link to the post with tons of pics on how I did the VFD and DRO upgrades if your interested :

https://www.hobby-machinist.com/threads/g9972z-dro-and-brushless-vfd-mods.104507/

Lastly i'm looking to move towards gunsmithing so I machined a spider assembly that threads on to my outboard M39x1.5mm spindle . Works perfect !

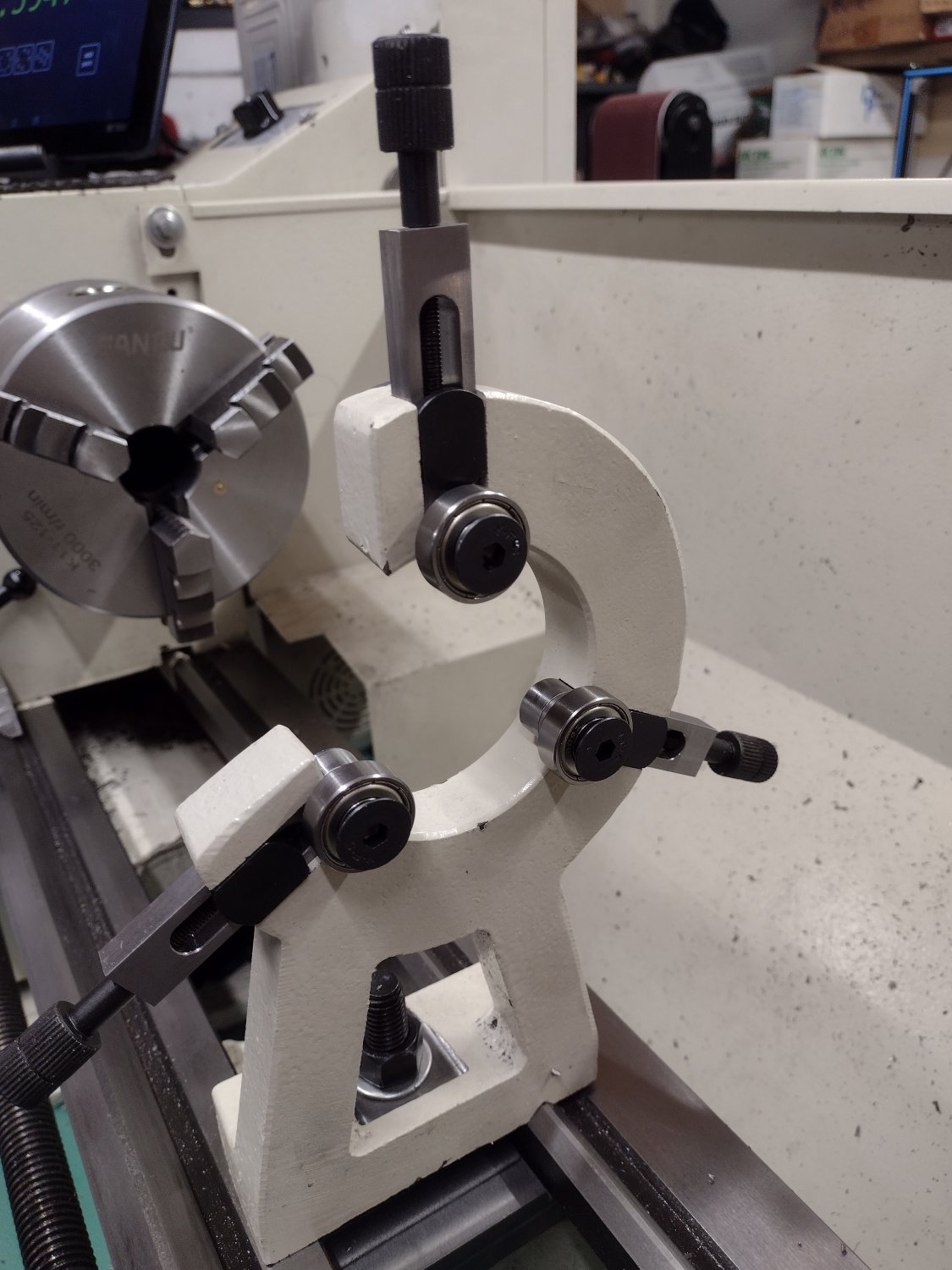

Also just finished modifying my steady rest to utilize bearings. I went with 608ZZ bearings and machined custom fingers. If need be I can accommodate a max 2.150" dia workpiece.

I have the Grizz 11x29 and it's almost identical to the 10x22 ( as far as component drivetrain design ). Thus far i've upgraded to a 2hp 1500W VFD system, and let me be clear what a HUGE improvement in low end torque. My previous min speed was 150 rpm's and that "can" be challenging with threading in blind bores or up against shoulders. With my VFD, and my belt configuration set at min speed I can get down to 41 rpm and that's VERY helpful for threading in certain circumstances where you don't have a large "runoff" area of material. The VFD spindle braking is almost instant so threading meteric (having to keep the half nut engaged) is far less risk of a crash. I also added a magnetic scale DRO system and that goes without saying. NO MORE tedious counting the dials ! Here's a link to the post with tons of pics on how I did the VFD and DRO upgrades if your interested :

https://www.hobby-machinist.com/threads/g9972z-dro-and-brushless-vfd-mods.104507/

Lastly i'm looking to move towards gunsmithing so I machined a spider assembly that threads on to my outboard M39x1.5mm spindle . Works perfect !

Also just finished modifying my steady rest to utilize bearings. I went with 608ZZ bearings and machined custom fingers. If need be I can accommodate a max 2.150" dia workpiece.