- Joined

- Oct 14, 2014

- Messages

- 2,115

This will be the third time doing a drive upgrade on the 10EE. Third times a charm

20 years ago, I installed a 3 phase motor and backgear using the design most everyone has done. Cut or replace the backgear shaft, install a coupling to the driving motor. This would work great but there is not enough room to do this right. The bearing on the backgear and the coupling are too close together. After only 20 years run the unit is starting to have an out of balance at high speed. No problem on a lesser lathe, but this is the 10EE -best toolroom lathe with enough ability to do larger parts too.

I'll just mention build two - 10hp 3phase and VFD no backgear.

www.hobby-machinist.com

This is a beautiful but expensive rebuild.

www.hobby-machinist.com

This is a beautiful but expensive rebuild.

The subject machine already has a small vfd running. So, route 2 would be expensive and the machine would be down for weeks. I have a spare backgear from build 2. So, this project can be completed and then do a motor swap in a day.

OK, for this build I will mount the backgear just like Monarch did it - direct to the motor shaft. The problem here is finding a motor with a long shaft. I scored one - see pic. Also the backgear housing must be mounted VERY carefully. No TIR allowed.

Here's the original motor with backgear removed. I re assembled this motor to get a measurement. The shaft is 2.700" long from the plate.

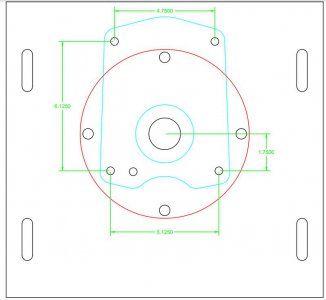

Here's a print - transfer plate is black, backgear is blue 3 phase motor ring is red.

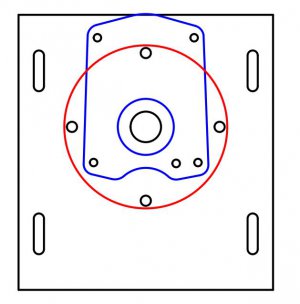

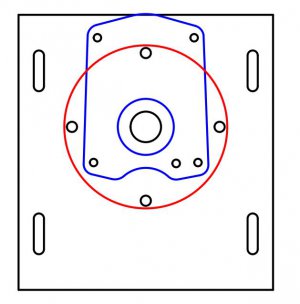

OK day one work was to carefully measure the backgear mounting and then double check it all by drilling a trial plate. I am SO GLAD I took the time to take this step - I had made a stupid transpose error that would not have been caught. This pic shows everything aligning just perfect on the backgear.

<EDIT> middle pic should be below - I screwd up and its above.

20 years ago, I installed a 3 phase motor and backgear using the design most everyone has done. Cut or replace the backgear shaft, install a coupling to the driving motor. This would work great but there is not enough room to do this right. The bearing on the backgear and the coupling are too close together. After only 20 years run the unit is starting to have an out of balance at high speed. No problem on a lesser lathe, but this is the 10EE -best toolroom lathe with enough ability to do larger parts too.

I'll just mention build two - 10hp 3phase and VFD no backgear.

Monarch 10EE rebuild 10Hp VFD no backgear

I bought my second 10EE a while back https://www.machinesused.com/lots/Monarch-10EE-Toolroom-Lathe-with-Taper-Attachment-and-Chucks-25097#bidNow After playing with the existing DC motor and drive, I gave up on repairing it. I did not try super hard, not too excited about maintaining an antique...

www.hobby-machinist.com

www.hobby-machinist.com

The subject machine already has a small vfd running. So, route 2 would be expensive and the machine would be down for weeks. I have a spare backgear from build 2. So, this project can be completed and then do a motor swap in a day.

OK, for this build I will mount the backgear just like Monarch did it - direct to the motor shaft. The problem here is finding a motor with a long shaft. I scored one - see pic. Also the backgear housing must be mounted VERY carefully. No TIR allowed.

Here's the original motor with backgear removed. I re assembled this motor to get a measurement. The shaft is 2.700" long from the plate.

Here's a print - transfer plate is black, backgear is blue 3 phase motor ring is red.

OK day one work was to carefully measure the backgear mounting and then double check it all by drilling a trial plate. I am SO GLAD I took the time to take this step - I had made a stupid transpose error that would not have been caught. This pic shows everything aligning just perfect on the backgear.

<EDIT> middle pic should be below - I screwd up and its above.

Last edited: