- Joined

- Nov 16, 2015

- Messages

- 9

Good morning.

I haven't been a super active member, but I picked up a Standard Modern 10" Utilathe last fall. I have not worked with a metal lathe in a lot of years, so complete newby is how I would describe myself.

I have been doing just basic straight cuts, mostly in wood, plastics and ebonite. I finally decided to give thread cutting a try, with disastrous results.

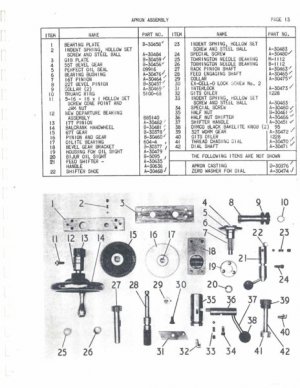

I set everything up to do a 1/2"-20 course thread. I am making a spare toolrest post for my woodlathe. I set the lathe speed to 75, the ABC-shifter to C, and the tumbler in the 3rd hole. Everything I have read, including the very thin manual I have, says that I should be able to engage the half-nut on any graduation of the threading dial. I tried this, and the threads were trashed on about the 3rd pass.

I made multiple attempts at this thread, each time on the 2nd-4th pass, the threads would be destroyed. I started to pay attention to where I engaged the half nut. I also tried only on numbered graduations as well as only on even numbered graduations. No luck. The only thing I haven't tried yet, is engaging the lead screw on the exact same graduation each time.

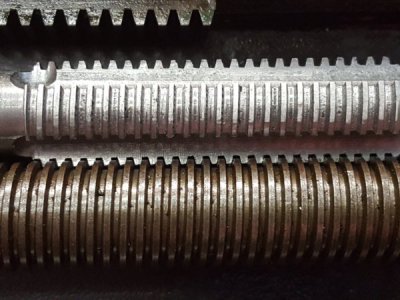

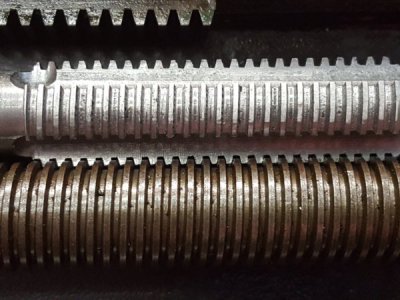

I finally started looking into the worm gear and lead screw. The guy I bought the lathe from said that he had replaced the worm gear with one made out of Delerin. I have the original chewed up gear, as well as a spare delerin gear. He also gave me a cutter that he used to cut the teeth into the worm gear.

This is what he gave me. The original gear is in the fixture on the right. The other downside, is I'm not sure how to use this fixture to make a new gear.

I counted the teeth on the Delerin worm gear, and there are 34T, The original is supposed to be 32T. I checked the cutter that he gave me, and it appears to mesh perfectly on the lead screw.

With my complete lack of experience, I am not sure what to do. I tried keeping the half-nut engaged, but there is not brake on this lathe. So out of three tries, I had three fails. getting the lathe to coast to a stop where I need it, is tedious and is going to take a lot of practice to do it consistently. The threads that I eventually need to be able to make, are very fine multi start threads, such as in a pen cap.

Any advice, thoughts or suggestions, would be greatly appreciated.

Darrin

I haven't been a super active member, but I picked up a Standard Modern 10" Utilathe last fall. I have not worked with a metal lathe in a lot of years, so complete newby is how I would describe myself.

I have been doing just basic straight cuts, mostly in wood, plastics and ebonite. I finally decided to give thread cutting a try, with disastrous results.

I set everything up to do a 1/2"-20 course thread. I am making a spare toolrest post for my woodlathe. I set the lathe speed to 75, the ABC-shifter to C, and the tumbler in the 3rd hole. Everything I have read, including the very thin manual I have, says that I should be able to engage the half-nut on any graduation of the threading dial. I tried this, and the threads were trashed on about the 3rd pass.

I made multiple attempts at this thread, each time on the 2nd-4th pass, the threads would be destroyed. I started to pay attention to where I engaged the half nut. I also tried only on numbered graduations as well as only on even numbered graduations. No luck. The only thing I haven't tried yet, is engaging the lead screw on the exact same graduation each time.

I finally started looking into the worm gear and lead screw. The guy I bought the lathe from said that he had replaced the worm gear with one made out of Delerin. I have the original chewed up gear, as well as a spare delerin gear. He also gave me a cutter that he used to cut the teeth into the worm gear.

This is what he gave me. The original gear is in the fixture on the right. The other downside, is I'm not sure how to use this fixture to make a new gear.

I counted the teeth on the Delerin worm gear, and there are 34T, The original is supposed to be 32T. I checked the cutter that he gave me, and it appears to mesh perfectly on the lead screw.

With my complete lack of experience, I am not sure what to do. I tried keeping the half-nut engaged, but there is not brake on this lathe. So out of three tries, I had three fails. getting the lathe to coast to a stop where I need it, is tedious and is going to take a lot of practice to do it consistently. The threads that I eventually need to be able to make, are very fine multi start threads, such as in a pen cap.

Any advice, thoughts or suggestions, would be greatly appreciated.

Darrin