- Joined

- Feb 7, 2013

- Messages

- 792

10" Atlas carriage modifications

I was tearing down my Atlas for the second time in 20 Yrs it was time to clean and paint. After I made the tailstock modifications I thought I would move on to the carriage. I noticed from years of neglect from prior owners the bed was in bad shape it was straight but had bad wear spots so I spent about three days scraping it straight and smooth again after a lot of measuring checking and double checking it is done. It turned out nice but I would never want to do it again.

- - - Updated - - -

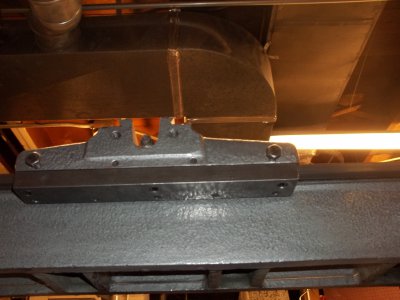

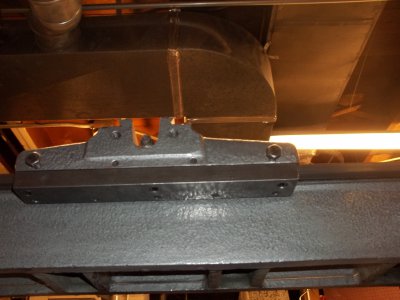

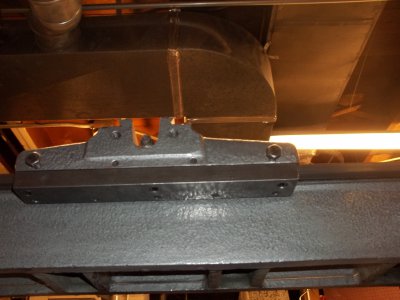

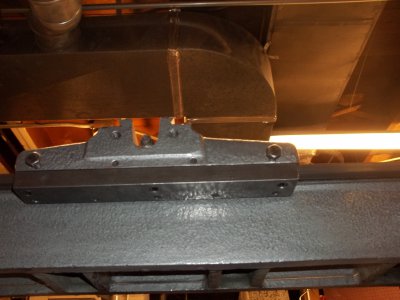

Notice the big gap under the carriage?? the carriage does not use very much of the way I built a small lathe before and it would cut much better than the atlas because I used all the surface area I could when I built it. I can do the same for this one as usual all mods can be changed back to stock.

- - - Updated - - -

There was some slight wear on the carriage so I flipped it upside down and set it up in my GO727 to mill it flat again but before I did that I cleaned up the bottom and purchased some loctitie epoxy it is twice as strong as JB Weld I was going to put a couple of screws in it but after it was set up I could not remove it without damaging the plate. The machined area will now be in contact with the bed is gives you about 1" per-side about 3" wide.

I then milled the surfaces so everything was flat again.

- - - Updated - - -

After a little paint and a lot of cleaning I reinstalled it and man what a differance it just glides up and down the bed with more contact surface it supports the weight a lot better.

But then I did not like the cheap thin Gibs and I really hated that you had to use shim stock to make them fit. I dont know about you but I can never seem to get that right so I thought I would change things and make them better.

- - - Updated - - -

For the rear gib I selected a piece of cold rolled 5/8 X 1 1/4 I then milled one side for a brass gib to go into. the extra (meat) will stiffen the carriage and it will allow me to make infinite adjustments. After I machined the slot for the brass gib I drilled and tapped for six 1/4 NF set screws.

- - - Updated - - -

Her is the finished product the rear gib is brass and is 5/16 x 1/2 and is adjusted by six fine thread set screws..The gib under the apron does not allow much so I took a piece of 3/8 X 1" brass bar an machined it to fit I then put set screws in it the original gib is only about 3/16 thick.. I will show you later how the adjustment is done.

- - - Updated - - -

This is the gib under the apron I tried to make one like the rear but there just is not enough room under there so this is what I come up with. You tighten down the three bolts till the carriage is tight then you just crack the bolts loose enough to get your desired fit you then tighten all the setcrews and re-tighten your bolts. The setscrews take the place of any shim stock and this will give you a very fine adjustment when there is not shim stock thin enough. Works great!

- - - Updated - - -

Here is the rear gib before paint on its test fit it performed as expected both gibs are much stronger gives the carriage more support and more surface contact than the stock ones. You can get a tigher tolerance with this setup and yet it slides up and down the ways with little effort.

- - - Updated - - -

Here are the stock gib plates next to the modified ones the new ones are more than twice as strong as the stock one and twice as thick it adjust much easyier and the brass glides along cast iron real nice. As I stated before I all ready built a lathe with these features on it and have tested it for years it works well and is well worth the time. Well thanks for lookin time to clean my shop now its a mess. Ray

I was tearing down my Atlas for the second time in 20 Yrs it was time to clean and paint. After I made the tailstock modifications I thought I would move on to the carriage. I noticed from years of neglect from prior owners the bed was in bad shape it was straight but had bad wear spots so I spent about three days scraping it straight and smooth again after a lot of measuring checking and double checking it is done. It turned out nice but I would never want to do it again.

- - - Updated - - -

Notice the big gap under the carriage?? the carriage does not use very much of the way I built a small lathe before and it would cut much better than the atlas because I used all the surface area I could when I built it. I can do the same for this one as usual all mods can be changed back to stock.

- - - Updated - - -

There was some slight wear on the carriage so I flipped it upside down and set it up in my GO727 to mill it flat again but before I did that I cleaned up the bottom and purchased some loctitie epoxy it is twice as strong as JB Weld I was going to put a couple of screws in it but after it was set up I could not remove it without damaging the plate. The machined area will now be in contact with the bed is gives you about 1" per-side about 3" wide.

I then milled the surfaces so everything was flat again.

- - - Updated - - -

After a little paint and a lot of cleaning I reinstalled it and man what a differance it just glides up and down the bed with more contact surface it supports the weight a lot better.

But then I did not like the cheap thin Gibs and I really hated that you had to use shim stock to make them fit. I dont know about you but I can never seem to get that right so I thought I would change things and make them better.

- - - Updated - - -

For the rear gib I selected a piece of cold rolled 5/8 X 1 1/4 I then milled one side for a brass gib to go into. the extra (meat) will stiffen the carriage and it will allow me to make infinite adjustments. After I machined the slot for the brass gib I drilled and tapped for six 1/4 NF set screws.

- - - Updated - - -

Her is the finished product the rear gib is brass and is 5/16 x 1/2 and is adjusted by six fine thread set screws..The gib under the apron does not allow much so I took a piece of 3/8 X 1" brass bar an machined it to fit I then put set screws in it the original gib is only about 3/16 thick.. I will show you later how the adjustment is done.

- - - Updated - - -

This is the gib under the apron I tried to make one like the rear but there just is not enough room under there so this is what I come up with. You tighten down the three bolts till the carriage is tight then you just crack the bolts loose enough to get your desired fit you then tighten all the setcrews and re-tighten your bolts. The setscrews take the place of any shim stock and this will give you a very fine adjustment when there is not shim stock thin enough. Works great!

- - - Updated - - -

Here is the rear gib before paint on its test fit it performed as expected both gibs are much stronger gives the carriage more support and more surface contact than the stock ones. You can get a tigher tolerance with this setup and yet it slides up and down the ways with little effort.

- - - Updated - - -

Here are the stock gib plates next to the modified ones the new ones are more than twice as strong as the stock one and twice as thick it adjust much easyier and the brass glides along cast iron real nice. As I stated before I all ready built a lathe with these features on it and have tested it for years it works well and is well worth the time. Well thanks for lookin time to clean my shop now its a mess. Ray

Last edited:

:tiphat:

:tiphat: