- Joined

- May 12, 2020

- Messages

- 2

Hi all. First post, hope this is in the right part of the forum.

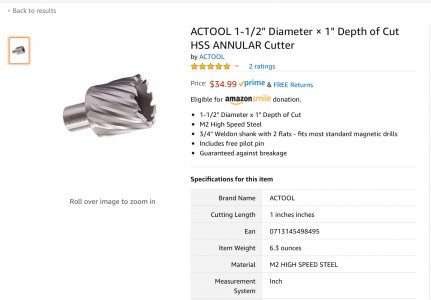

I'm a car guy and need to fabricate 4 exhaust flanges for a turbo application. The exact material isn't a big deal to me as long as I can weld it with my mig welder and it can withstand being in the exhaust stream. Existing products on the market are usually 3/8ths 1018 mild steel or stainless. The flange needs to have two non-threaded holes on either side of a 1.5" hole. See below-Doesn't need to have the extra machining on the inside edge of the 1.5" hole.

What is the best way to go about this for somebody who has no machining tools? My first thought was to buy my brother's vintage Craftsman 150 drill press-with a low speed third pulley it should go down to 175RPM (For a 1.5" twist bit I think that's about 69SFM). Unfortunately a lathe is out of the question because of storage and price concerns, as is a mill.

Am I on the right track with the Craftsman 150 running at 175RPM and a 1.5" twist bit?

I'm a car guy and need to fabricate 4 exhaust flanges for a turbo application. The exact material isn't a big deal to me as long as I can weld it with my mig welder and it can withstand being in the exhaust stream. Existing products on the market are usually 3/8ths 1018 mild steel or stainless. The flange needs to have two non-threaded holes on either side of a 1.5" hole. See below-Doesn't need to have the extra machining on the inside edge of the 1.5" hole.

What is the best way to go about this for somebody who has no machining tools? My first thought was to buy my brother's vintage Craftsman 150 drill press-with a low speed third pulley it should go down to 175RPM (For a 1.5" twist bit I think that's about 69SFM). Unfortunately a lathe is out of the question because of storage and price concerns, as is a mill.

Am I on the right track with the Craftsman 150 running at 175RPM and a 1.5" twist bit?