Hi,

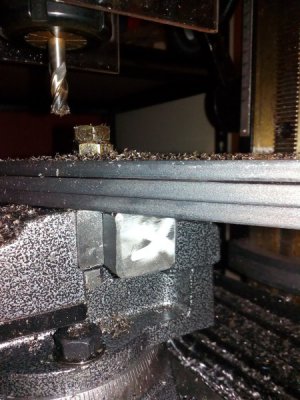

I'm using a minimill to try to make an approx. 1 3/4 inch dia. hole in about 3/4" thick steel (low carbon). I'm trying to work out what is a reasonable way to go about this. The mill has a stated drilling capacity of about 3/4" dia. from memory.

Do I drill a 3/4" hole and then use a lot of passes with a boring bar on a boring head to get the hole out to 1 3/4"?

Do I use an end mill to try make a circular pocket just a bit smaller than required and then use a boring bar on a boring head to finish off the rest?

Any other suggestions as to how to achieve this hole?

Cheers,

xxxx_guy

I'm using a minimill to try to make an approx. 1 3/4 inch dia. hole in about 3/4" thick steel (low carbon). I'm trying to work out what is a reasonable way to go about this. The mill has a stated drilling capacity of about 3/4" dia. from memory.

Do I drill a 3/4" hole and then use a lot of passes with a boring bar on a boring head to get the hole out to 1 3/4"?

Do I use an end mill to try make a circular pocket just a bit smaller than required and then use a boring bar on a boring head to finish off the rest?

Any other suggestions as to how to achieve this hole?

Cheers,

xxxx_guy