- Joined

- Jan 1, 2017

- Messages

- 31

Hello everyone!

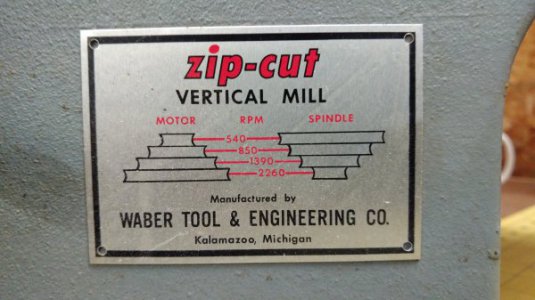

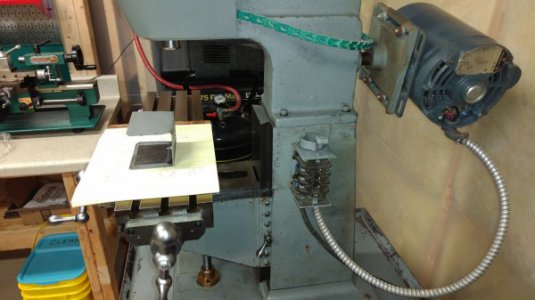

I just recently acquired my first vertical mill in a local estate sale. The mill is a Zip-Cut Vertical Mill made by Waber Tool & Engineering Co. Not sure of the vintage or how many of these were produced, but myself and ZIPandGRIZZ seem to own the only two out there. There is little to no information about these mills online and unfortunately I was unable to locate any documentation at the sale. The story I received was that this mill was previously owned by Western Michigan University, then put into storage, then ultimately acquired and brought home by one of the engineering professors.

The mill looks to be in great condition and I was surprised to even find cosmoline still covering many of the surfaces! Really the only wear can be attributed to storage in a slightly damp basement and a few superficial dings on the table.

Anyway lets get into it!

This is how I originally found it. Lots of sawdust from being in a basement wood shop.

After a good hour of breaking it down and pulling it out of the basement in pieces I was finally able to get it all into my car and home. Boy this thing was heavy!!

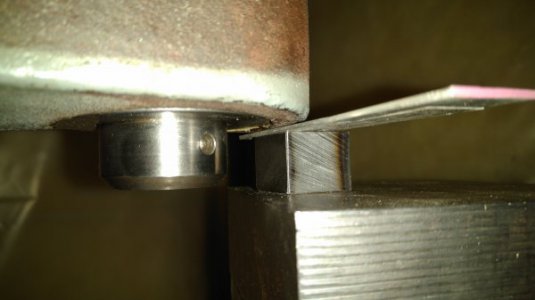

Time to really dive in and see how they put this guy together. Yup, that's the original cosmoline! And check out the flaked gib

Table off, and that's not rust! More cosmoline!

Closeup of the handle and dial. The leadscrew rides in a bronze bushing with two roller thrust bearings (more details on this later).

So here's a little step by step for tearing down one of these leadscrews. First remove the handle retaining screw and tap off the handle. The dial is held in place by a setscrew.

Watch out for that tiny woodruff key!

Loosen the setscrew (I removed it at first, don't lose the tiny brass pad) on the bearing retainer and unscrew from the leadscrew.

Disassembled

Time to remove the saddle! A couple of bolts and it can be slid off.

And more of that protective sawdust

Gibs

Time to remove the knee! And a closer look. Nice touch with the conic gear "umbrella"!

Here's the column. Little bit of surface rust and cosmoline but nothing a razor and some elbow grease can't take care of!

Time to break down the Y-axis. Note the threaded bushing retainer.

And here are the knee screws. Check out that oil grove!

That's all for now. Next up, time to clean! Hope you all enjoyed the pictures and breakdown. Expect more to come! And here's a little teaser!

I just recently acquired my first vertical mill in a local estate sale. The mill is a Zip-Cut Vertical Mill made by Waber Tool & Engineering Co. Not sure of the vintage or how many of these were produced, but myself and ZIPandGRIZZ seem to own the only two out there. There is little to no information about these mills online and unfortunately I was unable to locate any documentation at the sale. The story I received was that this mill was previously owned by Western Michigan University, then put into storage, then ultimately acquired and brought home by one of the engineering professors.

The mill looks to be in great condition and I was surprised to even find cosmoline still covering many of the surfaces! Really the only wear can be attributed to storage in a slightly damp basement and a few superficial dings on the table.

Anyway lets get into it!

This is how I originally found it. Lots of sawdust from being in a basement wood shop.

After a good hour of breaking it down and pulling it out of the basement in pieces I was finally able to get it all into my car and home. Boy this thing was heavy!!

Time to really dive in and see how they put this guy together. Yup, that's the original cosmoline! And check out the flaked gib

Table off, and that's not rust! More cosmoline!

Closeup of the handle and dial. The leadscrew rides in a bronze bushing with two roller thrust bearings (more details on this later).

So here's a little step by step for tearing down one of these leadscrews. First remove the handle retaining screw and tap off the handle. The dial is held in place by a setscrew.

Watch out for that tiny woodruff key!

Loosen the setscrew (I removed it at first, don't lose the tiny brass pad) on the bearing retainer and unscrew from the leadscrew.

Disassembled

Time to remove the saddle! A couple of bolts and it can be slid off.

And more of that protective sawdust

Gibs

Time to remove the knee! And a closer look. Nice touch with the conic gear "umbrella"!

Here's the column. Little bit of surface rust and cosmoline but nothing a razor and some elbow grease can't take care of!

Time to break down the Y-axis. Note the threaded bushing retainer.

And here are the knee screws. Check out that oil grove!

That's all for now. Next up, time to clean! Hope you all enjoyed the pictures and breakdown. Expect more to come! And here's a little teaser!