- Joined

- Oct 14, 2014

- Messages

- 1,966

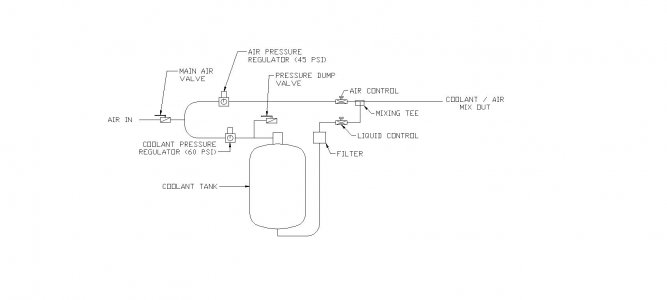

I’ve preferred a coolant mister over flood coolant on my machines without enclosures. The purchased units work well but they tend to put out a slight fog. If you spend 100s of hours in the shop you soon get sensitive to the smell. If you got $500 to spend a Henchforth Fog buster mister is the way to go. Being a cheap bastid, I looked up the patent and built my own in the late 90s. Built a better, generation 2 in 2002. Rather than re do all this older work, read these links:

original rec.crafts.metalworking thread 2002

https://groups.google.com/forum/?hl=en#!topic/rec.crafts.metalworking/zAzOhL8z3A4

short write up about my original zero fog mister

http://www.machinistblog.com/zero-fog-mister/

Other mister builds, nozzle info

http://www.cnczone.com/forums/general-metalwork-discussion/87439-cooling-hvlp-mist-producer.html

Great build thread

http://www.cnczone.com/forums/gener...nes/102934-built-fog-less-coolant-mister.html

original rec.crafts.metalworking thread 2002

https://groups.google.com/forum/?hl=en#!topic/rec.crafts.metalworking/zAzOhL8z3A4

short write up about my original zero fog mister

http://www.machinistblog.com/zero-fog-mister/

Other mister builds, nozzle info

http://www.cnczone.com/forums/general-metalwork-discussion/87439-cooling-hvlp-mist-producer.html

Great build thread

http://www.cnczone.com/forums/gener...nes/102934-built-fog-less-coolant-mister.html