- Joined

- Feb 8, 2014

- Messages

- 11,176

I am adding a Z-axis to my 2-axis Eagle CNC mill. This is a full upgrade project with a new computer, new software, and all new controls. I just installed the Z-axis scale today. These are 1 micron (0.000039 inch) resolution scales. That means I can position pretty close, that doesn't mean I can machine to that tolerance, it just means I have a fighting chance of getting kind of close.

All of the new magnetic scales are mounted on the machine now and are tied into the computer. The only thing left at this point is to build the Z-axis drive hardware. I removed all of the original quill feed hardware, don't think I'll be needing it any longer.

First I made a new quill stop to be able to mount the reader head. I wanted it pretty strong so I made it out of 4140.

Then I had to do a little machining on the head to clear the scale mount and new quill stop. I also flattened out the upper stop face to I could later mount the quill counter balance. I did this on my old mill that I sold to my friends at ADX Portland, they were kind enough to let me use it again.

While I was there I also located, drilled and tapped the mounting holes for the Z-axis drive hardware. I have the head clamped to an angle plate for this operation.

The next step was to mount the mag strip backing plate, I used the original scale mounting holes, but retapped them for 10-24 because was the size flat head screws I had in the drawer.

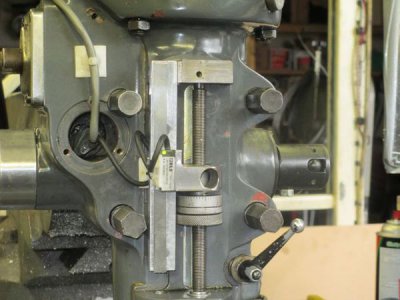

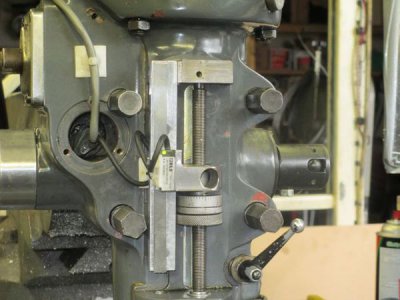

Here is the almost finished Z-scale install, I still need to make a proper cover for the big hole there. With all the quill feed hardware removed, it makes a nice junction box for the connection. The cable from the reader head tracks nicely right beside the head clamp bolts without binding. The magnetic strips are attached with a 3M 'it ain't never gonna come loose tape', pretty much resistant to every known coolant and oil.

The X-axis scale. I installed the X and Y axis scales in November, right in the middle of a job after the the original encoders failed.

The Y-scale.

The K-scale. Originally there was a glass scale on the knee axis. I used the original mounting hardware for that to mount the new magnetic scale. The knee will not be under computer control, but does show on the DRO screen.

The DC CNC controller screen. (EDIT: This is a really old version of my software)

All of the new magnetic scales are mounted on the machine now and are tied into the computer. The only thing left at this point is to build the Z-axis drive hardware. I removed all of the original quill feed hardware, don't think I'll be needing it any longer.

First I made a new quill stop to be able to mount the reader head. I wanted it pretty strong so I made it out of 4140.

Then I had to do a little machining on the head to clear the scale mount and new quill stop. I also flattened out the upper stop face to I could later mount the quill counter balance. I did this on my old mill that I sold to my friends at ADX Portland, they were kind enough to let me use it again.

While I was there I also located, drilled and tapped the mounting holes for the Z-axis drive hardware. I have the head clamped to an angle plate for this operation.

The next step was to mount the mag strip backing plate, I used the original scale mounting holes, but retapped them for 10-24 because was the size flat head screws I had in the drawer.

Here is the almost finished Z-scale install, I still need to make a proper cover for the big hole there. With all the quill feed hardware removed, it makes a nice junction box for the connection. The cable from the reader head tracks nicely right beside the head clamp bolts without binding. The magnetic strips are attached with a 3M 'it ain't never gonna come loose tape', pretty much resistant to every known coolant and oil.

The X-axis scale. I installed the X and Y axis scales in November, right in the middle of a job after the the original encoders failed.

The Y-scale.

The K-scale. Originally there was a glass scale on the knee axis. I used the original mounting hardware for that to mount the new magnetic scale. The knee will not be under computer control, but does show on the DRO screen.

The DC CNC controller screen. (EDIT: This is a really old version of my software)

Last edited: