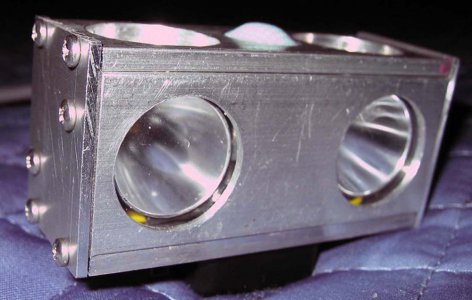

I've been building my own bicycle lights using high power LEDs for several years, and the case is always the most difficult part, by far!

My shop is stuffed pretty full of wood working equipment, and my metal working power tools consist of a floor standing Delta drill press equipped with a Harbor Freight cross vise, a Makita miter saw, and my Craftsman table saw with a fine tooth blade. I work with aluminum only. My case design is put together to work around the limitations of my shop. I'd love to have a milling machine and lathe, but I can't justify the investment at this time.

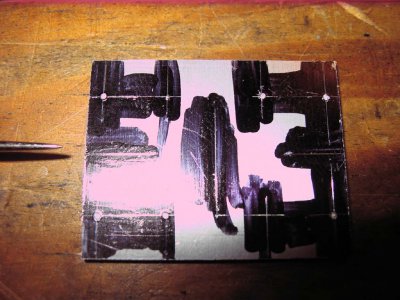

The case I'm working on is constructed using 1" square aluminum tubing and various bits of flat aluminum plate joined with small machine screws. The screws need to be located to ~+- 0.002" or so for everything to go together well.

In the course of generating lots of scrap pieces, I've come to the conclusion that my next tool investment should be a better x-y table. The main failings of the Harbor Freight table I'm looking to replace are:

-Lots of lash in the screw drive mechanism.

-The cinching (not sure of the correct term) screws that hold the table in place (needed due to screw lash) are too small to crank down hard, and are in spots that can be difficult to reach.

-The vise is inconvenient and will be replaced with something like a Wilton cam-lock model.

My question to the folks here at Hobby Machinist is, what is the best x-y table I can get in the $200-$300 range that will address these issues? I've looked at models from Grizzly, Enco, Proxxon, and The Little Machine Shop. They all look OK, but don't list in their on-line specs what I'm interested in.

Walt

My shop is stuffed pretty full of wood working equipment, and my metal working power tools consist of a floor standing Delta drill press equipped with a Harbor Freight cross vise, a Makita miter saw, and my Craftsman table saw with a fine tooth blade. I work with aluminum only. My case design is put together to work around the limitations of my shop. I'd love to have a milling machine and lathe, but I can't justify the investment at this time.

The case I'm working on is constructed using 1" square aluminum tubing and various bits of flat aluminum plate joined with small machine screws. The screws need to be located to ~+- 0.002" or so for everything to go together well.

In the course of generating lots of scrap pieces, I've come to the conclusion that my next tool investment should be a better x-y table. The main failings of the Harbor Freight table I'm looking to replace are:

-Lots of lash in the screw drive mechanism.

-The cinching (not sure of the correct term) screws that hold the table in place (needed due to screw lash) are too small to crank down hard, and are in spots that can be difficult to reach.

-The vise is inconvenient and will be replaced with something like a Wilton cam-lock model.

My question to the folks here at Hobby Machinist is, what is the best x-y table I can get in the $200-$300 range that will address these issues? I've looked at models from Grizzly, Enco, Proxxon, and The Little Machine Shop. They all look OK, but don't list in their on-line specs what I'm interested in.

Walt

But really expensive $800 + Dollars Ouch!!!

But really expensive $800 + Dollars Ouch!!!