- Joined

- Sep 11, 2014

- Messages

- 76

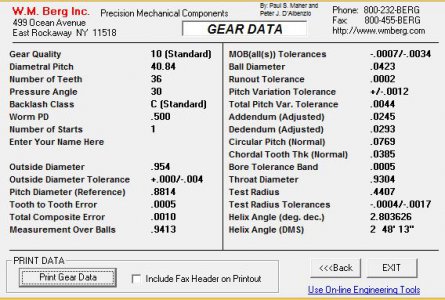

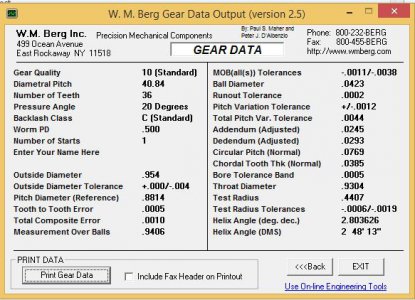

One of my challenges of understanding these formulas is not knowing what the datum really mean and what is their expected values, I racked my brains until the lights went on. When we look at the worm screw its described as 1/2-13, a screw nominal size and the number of threads per inch (TPI a rate). Additionally we can compute the actual size of a single thread, the pitch or circular pitch (CP a measurement), 1/13 = 0.076923. So when we use a formula DP = pi / CP this results in 3.14 / .0769 = 40.84 But if you use DP = TPI x pi you get 13 x 3.14 = 40.84 its the same value. In my mind the relationship between the worm screw TPI (13) and the worm gear DP (40.84) now becomes very apparent and the computed or derived values are reasonable and make sense.

This thread gave me the opportunity to learn and once understood to be able to apply the knowledge in differing ways.

Thanks,

Caster

This thread gave me the opportunity to learn and once understood to be able to apply the knowledge in differing ways.

Thanks,

Caster