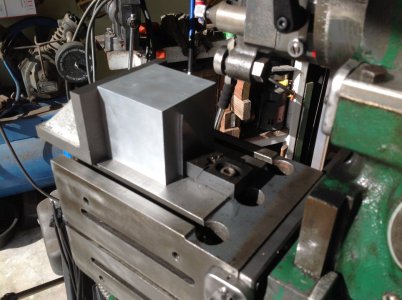

I have a Burke #4 horizontal milling machine that only has a single T-slot. Usually, I use a vice clamped using T-nuts. What are some options for clamping when the work is too big for the vice? I have a piece that I want to put a slot in, but wouldn't something like strap clamps just get in the way of the horizontal cutter?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Work holding with single T-Slot

- Thread starter Cortez

- Start date

- Joined

- Jan 20, 2019

- Messages

- 102

You can make a fixture plate the bolts to the table with countersunk bolts and drill the plate as needed for clamping

You can use multiple clamps and remove/replace them as the milling progresses down the length.

You can use the t-slot as a v-block to align the part, but then you’d only be able to clamp at the ends; unless you use something like the fixture plate mentioned above.

You can use the t-slot as a v-block to align the part, but then you’d only be able to clamp at the ends; unless you use something like the fixture plate mentioned above.

- Joined

- Feb 9, 2017

- Messages

- 5,254

It would help to see what you’re getting into. The beauty of a horizontal is like the shaper in that the force being applied is linear to the slot. So a shop made what they called a dog or angle plate as your stop at one end with toe clamps at the other end have done it for me. It all depends on how tall the work is. Shorter closer to the table is better but for tall stuff an appropriate angle plate as backstop has done the job too.