Guess I'm late to the party, but here are a few things I've stumbled onto (or into) while working with several treadmill conversions. Others have mentioned some of them. Three sets of motors and controls are in use on my lathe, mill, and drill press; and there's one slated for the vertical bandsaw and possibly another for the horizontal. I love these things.

- Almost all the motors have flywheels with 1/2-13 LH threads. Nuts and taps are readily available.

- The easy way to get the flywheel off is to run the motor forward and then stop the shaft suddenly. The easy way to do that is to set up a SPDT switch in one side of the line, wired so in one position it feeds the motor, and in the other, it opens the line and shorts the motor. (See below for more on this.) I do have a couple of 3 HP motors that use a keyed shaft.

- The flywheel will add momentum to the tool, for better or worse. It's kind of like using a sledgehammer instead of an engineer's hammer. It's harder to stop, which I wouldn't like if I were tapping a hole because it could break your tap if it bogged down. In fact, I'd rather have a slip clutch for tapping.

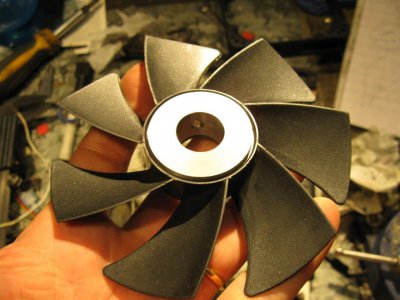

- The flywheel usually has fan blades that provide cooling in proportion to the speed. But the main point of using a DC motor with PWM is that you can create a lot of torque at low RPM, and that takes a lot of current that produces a lot of heat. Better to use a PC fan that runs full speed all the time, with the bonus of continuing to cool the motor down after it stops. This is another reason to lose the flywheel.

- These motors have incredibly strong permanent magnets. They're great for cleaning up your chips and filings around the shop - they'll pick up every last little shard. Problem is, they weren't designed for machine shops. I put duct tape over the openings as soon as I can get to them, and don't take it off until you have to. Part of the retrofit requires making some sort of shield and screen to keep stuff from getting drawn in by the combination of magnetism, cooling airflow, and Murphy's Law.

- The pot is usually 5K and always linear. The value isn't critical, but I wouldn't go below 1K or above 10K without some electronics investigation. It's important that it be linear, not audio or log, to keep the speed proportional to how far you turn the dial. (If you're into that stuff, the reason the resistance isn't critical is that the pot is a voltage divider feeding a high impedance, carrying little current, so value is not a big deal. And with the other nonlinear pots, the speed changes pretty fast at one end, and pretty slow at the other.)

- Treadmills can be shut down by the feedback loop that tells the controller how fast the motor is going. The controller compares this with the speed control setting (pot) and cranks up or down the juice as needed to maintain the target speed, even as the load varies. That can be helpful for things like avoiding chipping carbide tips. Say you're milling an irregular piece of stock that isn't uniformly hardened (think case-hardened, or unseasoned cast iron, for example), and the speed is bogging down so you crank the pot and the speed comes back up. Then if you hit a hollow or soft spot, the mill speeds way up almost instantly, and you slide right through the hollow only to have the tips hit the case-hardened surface on the other side, and bang! Carbide doesn't like shocks like that - though it's really hard and takes hi temp beautifully, it just can't handle impact.

- Some controllers will shut the motor down if they don't get a signal back indicating that it's moving. Most treadmills use a magnet or stripes on the flywheel and a coil or phototransistor nearby on the frame to create the signal. Problem comes after you remove the flywheel and lost the signal generator. You can fabricate a substitute, too complicated to go into here, but I would be glad to explain offline.

- About stopping the motor with a switch: Actually, this is pretty effective. Here's how it works: a motor and a generator and one and the same, though optimized differently. A spinning motor generates a voltage proportional to its speed. If you disconnect the power and then put a low resistance across the motor terminals, current flows with the effect of slowing the motor down rapidly. I’ve got a kill switch on my lathe that does just this, and it stops the chuck in less than 1 second.

- Most switches and relays can't handle nearly as much current when it's DC as when it's AC. Look for switches rated at least 10 amps at 110 VDC. They can be hard to find, and you may have to settle for something less. Just be aware that they can overheat, open the circuit (cutting power to the motor), short the power (could fry the controller, although you can minimize the risk by putting a fuse between the controller and the reversing or shorting switch going to the motor; or - perhaps worst of all, it could flake out and suddenly turn on when you have it in the off position.

- Because unintended start-up could be disastrous to the operator, as well as the tooling, the machine, and the work, I would ALWAYS PUT A RELIABLE, ADEQUATELY RATED DPDT SWITCH IN THE AC LINE BEFORE THE CONTROLLER, IN A VERY HANDY LOCATION, AND ALWAYS SWITCH IT OFF WHEN NOT USING THE MOTOR. This is the only way to be sure the motor won't start up without warning.

- About opening the pot's center lead to turn the motor off: I would use the same AC line switch as above to kill the power absolutely for sure before assuming the motor will never start up on its own. I don't pretend to know a lot about machining, or everything about electronics, but I do have a lot of years worth of surprises and scars because I assumed circuitry was dead when it wasn't. Components fail, solder joints break - both aggravated by the vibration that machines inevitably create.

I would either buy or build a metal box, just for fire safety.

I would either buy or build a metal box, just for fire safety.