- Joined

- Apr 20, 2011

- Messages

- 430

Any body that has an Asian tool with electrics knows that "they aint the same".

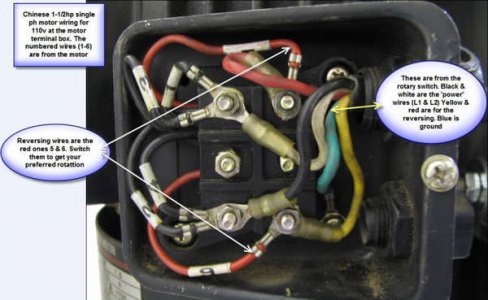

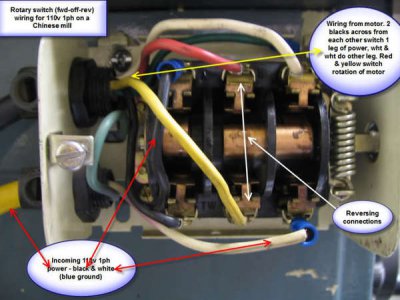

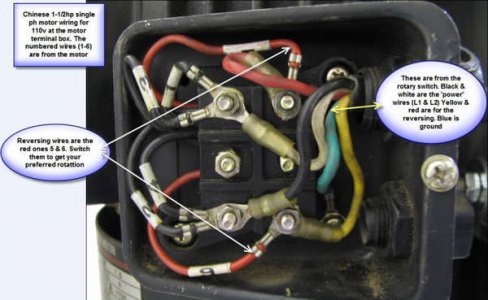

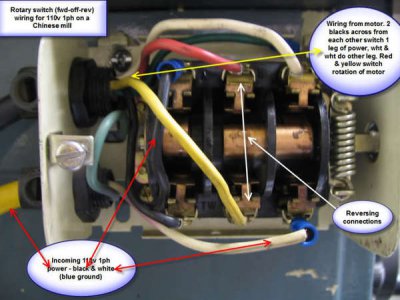

Remember here --- THIS IS FOR 110v, and, This procedure was on a 1-1/2hp 1ph Asian motor, yours may be different -- 220v is different.

Having recently spent some frustrating time getting a mill drill motor & rotary/reversing switch converted over to 110v, I thought I'd share some pics I took, with some added 'balloons' pointing out how it ended up - maybe it'll help somebody down the road.

In the few instances I've seen, the wiring number system out of the motor is the same except for the reversing wires being numbered 5 & 6, instead of the American system of them being 5 & 8, but, seems the makeup/design on switches may be otherwise...

A tip: While chasing the wiring on this thing I was typically using a meter to 'ring' the wires - suddenly I thought of getting my small 12v battery charger and hooking it up as a substitute power source, I quickly had it figured out... Surprisingly, the 1-1/2hp universal motor would turn slightly which was a help in getting the CW/CCW right on the sw.

Editing --(Sorry on the post, some how the gremlins chopped some text and pics off)

Remember here --- THIS IS FOR 110v, and, This procedure was on a 1-1/2hp 1ph Asian motor, yours may be different -- 220v is different.

Having recently spent some frustrating time getting a mill drill motor & rotary/reversing switch converted over to 110v, I thought I'd share some pics I took, with some added 'balloons' pointing out how it ended up - maybe it'll help somebody down the road.

In the few instances I've seen, the wiring number system out of the motor is the same except for the reversing wires being numbered 5 & 6, instead of the American system of them being 5 & 8, but, seems the makeup/design on switches may be otherwise...

A tip: While chasing the wiring on this thing I was typically using a meter to 'ring' the wires - suddenly I thought of getting my small 12v battery charger and hooking it up as a substitute power source, I quickly had it figured out... Surprisingly, the 1-1/2hp universal motor would turn slightly which was a help in getting the CW/CCW right on the sw.

Editing --(Sorry on the post, some how the gremlins chopped some text and pics off)