- Joined

- Nov 22, 2010

- Messages

- 371

Hi guys & Gals

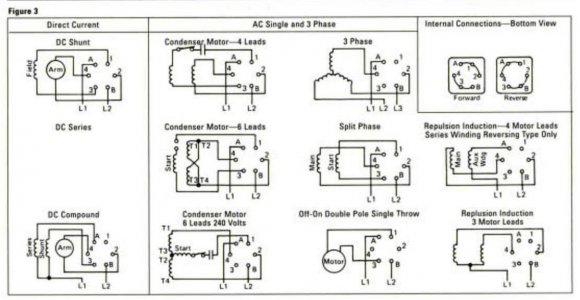

I bought a Logan 825 about 6 Months ago and it ran fine at the sellers house. he disassembled it for me to take home and removed the upright pole that holds the FURNAS motor reversing switch and disconnected it from the junction box on the peerless 1/2 hp 110-230 volt motor I now have a cord with a plug on one end to plug the lathe in but it is not wired to the motor or drum switch....I also have a Furnas drum assy that is wired to the drum but not to the motor or plug in cord .. the motor has a junction box that contains contains 3 wires with metal bands labled T-1 T-4 and C-1 also have a cluster of wires all wired together and capped off labled T-2, T-3 C-2 I know irt was running on 110 when I bought it as I ran it and tested it out:thinking:

Might anyone have a wiring diagram that could help me get it properly wired ??? Or a suggestion how to get it done

I have erbuilt the machine but I am just terrible with electric....always have been and I guess I always will be:whiteflag:

Thanks

Joe biplane

I bought a Logan 825 about 6 Months ago and it ran fine at the sellers house. he disassembled it for me to take home and removed the upright pole that holds the FURNAS motor reversing switch and disconnected it from the junction box on the peerless 1/2 hp 110-230 volt motor I now have a cord with a plug on one end to plug the lathe in but it is not wired to the motor or drum switch....I also have a Furnas drum assy that is wired to the drum but not to the motor or plug in cord .. the motor has a junction box that contains contains 3 wires with metal bands labled T-1 T-4 and C-1 also have a cluster of wires all wired together and capped off labled T-2, T-3 C-2 I know irt was running on 110 when I bought it as I ran it and tested it out:thinking:

Might anyone have a wiring diagram that could help me get it properly wired ??? Or a suggestion how to get it done

I have erbuilt the machine but I am just terrible with electric....always have been and I guess I always will be:whiteflag:

Thanks

Joe biplane