- Joined

- Jan 20, 2013

- Messages

- 272

Wine Bottle Stoppers

In my opinion, this is a really cool machine shop project and they make GREAT gifts. I have made a lot of these and we have given them away for all occasions. Even my wife loves them. After making some of these and giving them out, I think she even feels a little less like my hobby is just an excuse to buy tools and metal!

You can also seal beer and soda bottles with these. I know at least a few of you are thinking, "Who has left over wine?". Well, my doctor says a glass a day is better than a bottle once a week.

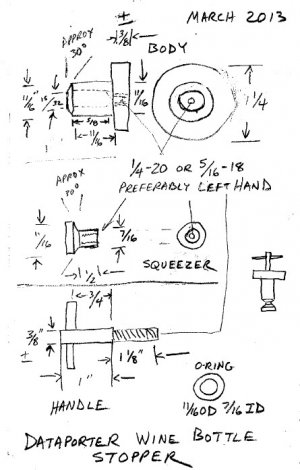

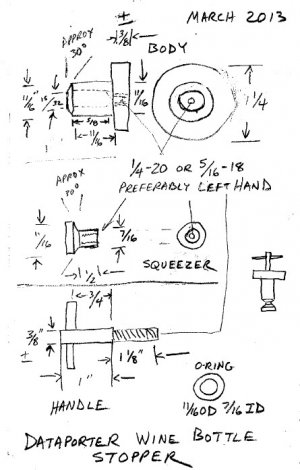

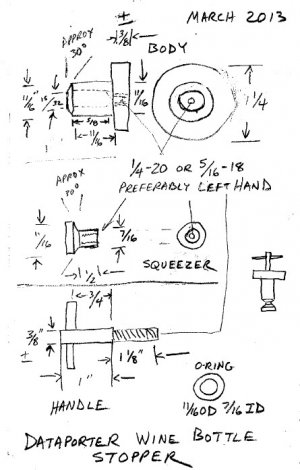

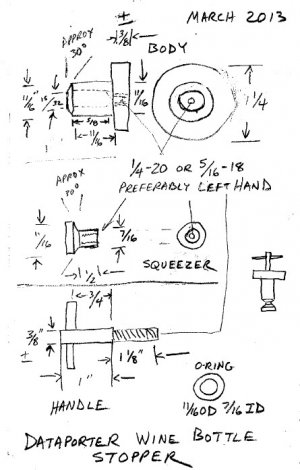

Even a beginner should have little trouble making these. None of the dimensions are critical. I have shown and attached a rough blue print to get someone started. On purpose, I have never made two of them the same! The 11/16" diameter of the stopper body will fit the neck of the overwhelming majority of wine bottles. I have seen a few smaller necked bottles and for those I have made some with a 5/8" diameter. The 5/8" will also work in the 11/16 bottles, that shows you how uncritical the dimensions are.

I use stainless steel for most of the parts. 303 is pretty easy to machine and 304 only slightly harder. The parts that go in the bottle especially should be stainless so they don't react with the wine. I even use food grade O-rings with 7/16" inside diameter 11/16" outside.

Sometimes I cut the body from a solid 1-1/4" or 1-1/8" or even one inch rod, I've use both round and hex stainless. You could even start with square. Sometimes I use 11/16" round for the part that goes into the bottle and press fit a "head" on to it. There is a little less waste that way and you can let your imagination run wild on how you make the head. The 30 degree angle on the end of the body and on the squeezer forces the o-ring out and against the neck of the bottle without pinching and ruining it. This angle is not critical, a little less might be better.

The threads are best if they are left hand threads, but they don't have to be. Because you are pulling the o-ring squeezer up or into the body, the left hand threads make the handle turn for the user righty tighty lefty loosey. I sometimes single point the threads on the handle, I even think cutting left hand threads is easier than right hand. But lately, I just buy a piece of stainless left hand threaded rod (allthread) and then I tap into both the handle and the squeezer and cut the allthread to size. Frankly, the allthread is faster and easier. You could also use a bolt to make the handle. Once I've got the length of the threaded part to where it functions like it should, I put a little thread locker on the end of the threads to keep it from unscrewing.

I'm designing and experimenting now with using a lever action eccentric instead of threads to expand the o-ring. So, there is really no end to the design possiblities.

So in conclusion, I hope you have as much fun making these and giving them away as I have. When you give one of these away to the wine lover, they truly have a "unique" gift that they will appreciate for years and think of you every time they have a glass!

Please enjoy responsibly ;-) Dave

View attachment WineStopperPlan.pdf

In my opinion, this is a really cool machine shop project and they make GREAT gifts. I have made a lot of these and we have given them away for all occasions. Even my wife loves them. After making some of these and giving them out, I think she even feels a little less like my hobby is just an excuse to buy tools and metal!

You can also seal beer and soda bottles with these. I know at least a few of you are thinking, "Who has left over wine?". Well, my doctor says a glass a day is better than a bottle once a week.

Even a beginner should have little trouble making these. None of the dimensions are critical. I have shown and attached a rough blue print to get someone started. On purpose, I have never made two of them the same! The 11/16" diameter of the stopper body will fit the neck of the overwhelming majority of wine bottles. I have seen a few smaller necked bottles and for those I have made some with a 5/8" diameter. The 5/8" will also work in the 11/16 bottles, that shows you how uncritical the dimensions are.

I use stainless steel for most of the parts. 303 is pretty easy to machine and 304 only slightly harder. The parts that go in the bottle especially should be stainless so they don't react with the wine. I even use food grade O-rings with 7/16" inside diameter 11/16" outside.

Sometimes I cut the body from a solid 1-1/4" or 1-1/8" or even one inch rod, I've use both round and hex stainless. You could even start with square. Sometimes I use 11/16" round for the part that goes into the bottle and press fit a "head" on to it. There is a little less waste that way and you can let your imagination run wild on how you make the head. The 30 degree angle on the end of the body and on the squeezer forces the o-ring out and against the neck of the bottle without pinching and ruining it. This angle is not critical, a little less might be better.

The threads are best if they are left hand threads, but they don't have to be. Because you are pulling the o-ring squeezer up or into the body, the left hand threads make the handle turn for the user righty tighty lefty loosey. I sometimes single point the threads on the handle, I even think cutting left hand threads is easier than right hand. But lately, I just buy a piece of stainless left hand threaded rod (allthread) and then I tap into both the handle and the squeezer and cut the allthread to size. Frankly, the allthread is faster and easier. You could also use a bolt to make the handle. Once I've got the length of the threaded part to where it functions like it should, I put a little thread locker on the end of the threads to keep it from unscrewing.

I'm designing and experimenting now with using a lever action eccentric instead of threads to expand the o-ring. So, there is really no end to the design possiblities.

So in conclusion, I hope you have as much fun making these and giving them away as I have. When you give one of these away to the wine lover, they truly have a "unique" gift that they will appreciate for years and think of you every time they have a glass!

Please enjoy responsibly ;-) Dave

View attachment WineStopperPlan.pdf